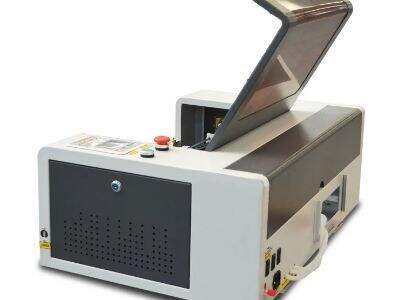

Аутомобилски сектор све више се ослања на ласерско обележавање. Ова технологија омогућила је произвођачима аутомобила да важне информације налепче на делове. Може да приказује слике као што су серијски бројеви, штрих кодови и логотипи. Ово је невероватно корисно за праћење делова, осигурање да све звучи исправно. Војерн је на челу овог покрета са нашим најсавременијим ласерским системом за обележавање који су брзи и прецизни. Ова прича ће детаљно рећи шта купци треба да знају и који су најновији трендови у технологији ласерског обележавања аутомобила

Ево шта купувачи аутомобила треба да знају

Када купују аутомобил, не много људи можда размишља о томе како су делови означени. Али ово је важно! Делотне информације помажу произвођачима да прате све ствари. На пример, ако постоји проблем са одређеним аутомобилом, агенти могу брзо да погледају да ли су делови погођени. Ово је од кључне важности за безбедност и квалитет. Користимо наш ласер да би означили возило и купци би требали бити свесни да има већи ниво тражимости. То значи да ако нешто не иде како треба, произвођач може да прати шта се догодило и да га лакше поправи.

Штавише, ласерско обележавање је изузетно издржљив. Ознаке не нестају или се не одмарају са употребом што је лепо за делове који ће бити врући / хладни и у неким случајевима хемикалије. Плус, то је чист процес. За разлику од тога, ласерско обележавање не уводе додатне материјале као што су налепнице или боја које се могу носити. То је такође боље за животну средину. Војернова машина за ласерско обележавање је брза и поуздана. Другим речима: Произвођачи аутомобила могу да се ослањају на информације које се налазе у њиховим деловима све док ти делови постоје у аутомобилу

Купци би такође требали узети у обзир брзину производње. Ласерско обележавање је брзо, тако да произвођачи аутомобила могу да изграде више аутомобила за мање времена. Таква брзина може бити од помоћи када је у питању одржавање ниских трошкова, а то је увек добро за потрошаче. Када се потрошачи свесни тога, они могу видети потребу за ласерским обележавањем у возилима и постају прозивнији приликом куповине аутомобила

Дакле, Који су најновији напредак ласерског обележавања за аутомобилске поље

Технологија ласерског обележавања развија се брзим темпом. Један од других великих напредовања је могућност означења на различитим врстама материјала. До недавно је ласерско обележавање обично примењивано на металу. Данас може да се нацрта на пластици, стакла, па чак и на гуми. То је од кључног значаја за аутомобилску индустрију, која користи различите врсте материјала у производњи аутомобила. На пример, на приборним плочама, предњим светлима и компонентама мотора може се примењивати ласерско обележавање

Још један занимљив развој је увођење специфичних боја у ласерском обележавању. Старији системи су могли да обележавају само црно-бело. Сада, нове методе остављају за собом шарене ознаке. Ово се такође може користити за брендирање или за побољшање изгледа компоненти. Једна од боја је логотип све светле и сјајне на сјајном аутомобилском делу, који чине аутомобил издвајају више

Поред тога, брзина означења опреме за ласерско означење се побољшава. Сада могу да обележе хиљаде делова за неколико сати. За компаније које морају да задовољавају велику потражњу, то је велика ствар. Војерн води ову технологију са бржим, способнијим машинама

Коначно, постоји тенденција повећања у аутоматизацији процеса означења. Многи произвођачи користе роботе како би им помогли у обележавању. То убрза процес и побољшава прецизност. Квалитет је стабилан када је све аутоматизовано, каже он, и увек је исправно означено. Ово је веома важно у аутомобилској индустрији да би се гарантовала безбедност и поузданост аутомобила

У закључку, индустрија ласерског обележавања сигурно игра незаменљиву улогу у аутомобилској индустрији. Уз Воиернове иновације, произвођачи аутомобила могу да производе аутомобиле који су не само безбеднији већ и привлачнији. Купци могу да се смире, јер су њихова возила произведена са врхунском технологијом која подржава квалитет и ефикасност

Na šta bi kupci trebalo da obrate pažnju

Ево неколико кључних тачака које треба узети у обзир приликом куповине опреме за ласерско обележавање за аутомобилски сектор. Прво морате да одлучите коју врсту ознаке желите да направите. Различити ласери се могу користити за прављење различитих знакова, као што су шифрова, серијски бројеви или логотипи. Такође морате изабрати ласер који је способан да обележи на начин на који желите. На пример, ако имате делове са веома прецизним детаљима, најбољи је ласер од влакана. Затим узмите у обзир предмете које ћете означити. Пет делова возила који се могу произвести од метала, стакла или пластике Оба ова материјала одговарају ласерско обележавање на посебан начин. Уверите се да је ласер који изаберете компатибилан са материјалима које планирате да користите

Још један кључни фактор је брзина. Време је новац у [автомобилској] индустрији. Ласерско обележавање такође може бити споро, што потенцијално смањује пролаз. Тражите ласер који ће брзо означити и не губи квалитет. То ће помоћи да производне линије буду у покрету док се испуњавају рокови испоруке. Такође размисли о величини материјала који ћеш означити. Неки ласери се ограничавају на мале делове, али други могу обележити веће делове. Уверите се да је опрема одговарајућа за величину ваших предмета

Коначно, размислите о подршци и услузи коју пружа снабдевач од кога купујете. Служба за кориснике је важна, посебно када се ради са компликованим машинама. Треба да будеш у стању да добијеш помоћ ако твој ласер не ради. Вероватно сте чули за њих, јер нуде одличну подршку, тако да не морате да бринете о кајању купца. Када узмете у обзир ове ствари, то вам помаже да изаберете најбољу опрему за ласерско обележавање за своје потребе

Савети за ефикаснију аутомобилску производњу са ласерским обележавањем Који су кључни разлози када се трансформише ваш процес како би се стекла конкурентна предност

Решења за ласерско обележавање су кључна у потрази за ефикасност у аутомобилској индустрији. Први корак је да се ухватиш за тренутну ситуацију. Видети колико времена траје маркирање и схватити шта је споро. Постоји неколико подешавања која можда желите да подесите за бољу брзину. На пример, ако је ласер ради превише споро да буде квалитетна ознака експеримент са бржим подешавања док траже изгоре или искривљавање вашег ознаке

И распоред ваше производње. Ако је станица за обележавање удаљена од места где се делови спајају, то може потрајати доста времена. Покушајте да пронађете станицу за ласерско обележавање близу краја контејнерске линије. На тај начин, радници могу лако да померају делове и да их извуку са малим кашњењем. Такође, сада имају аутоматизацију која може да убрза темпо. Аутоматски системи могу брзо да пребацују делове до и из ласера, одржавајући стабилан рад без прекида за раднике који то раде ручно

Такође је од суштинског значаја обучавање запослених како да оптимално раде на ласерским машинама за обележавање. Уверавајући се да су сви радници обучени како правилно да користе ове машине, она може помоћи да се спрече несреће због грешака. Ми пружамо решења обуке овде у Воиерну где ваш тим може научити најбоље методе за коришћење ресурса за ласерско обележавање. Утврђивање ласерских машина такође је велики део максимизације процеса. Поддржење машина у добром радном стању помоћи ће да се спрече врсте падова који заустављају производњу. Редовно их уређујте и чистите да би све било у реду. Следећи ове кораке, моћи ћете да повећате продуктивност и ефикасност на вашој производњи ласерски маркирање линије који вам помажу да добију бољи перформансе у аутомобилској индустрији

Где можете добити поуздане ласерске машине за обележавање за аутомобилску индустрију

Можда се чини да је изазов наћи добре ласерске машине за обележавање за аутомобилске апликације, али на тржишту постоје невероватне опције. Почните са тражењем путем истраживања предузећа која нуде ласерско обележавање технологија. Тражите компаније које имају добру репутацију, као што је Воиерн, и одаберете само произвођаче који производе висококвалитетну опрему посебно направљену за аутомобилске апликације. Добра репутација обично указује на то да компанија постоји довољно дуго и да је служила довољно купаца да су људи срећни

Када сте пронашли неке кандидате, прегледајте које производе могу понудити. И проверите да ли имају избор ласера, одговарајући за различите задатке обележавања. Такође је добро да прегледате рецензије и сведочанства купаца. То вам може дати идеју о томе колико добро опрема ради и колико је компанија поуздана. Размислите о томе да пронађете студије случаја или конкретне примери како друге аутомобилске компаније користе своје ласере, ако је могуће. Ова информација може бити корисна у пружању увид у то како опрема може радити за ваше потребе

Додатна тачка је гаранција и подршка. Точна гаранција може заштитити вашу инвестицију. То показује да компанија верује у своје производе. Такође би требало да прочитате како функционише њихов одјељ за корисничку услугу. Желите да се одмах обратите ако имате питања или вам је потребна помоћ. Воиерн је познат по врхунском сервису за купце који га чини доступнијим за предузећа која требају помоћ. На крају, проверите око себе. Иако је квалитет важан, не би требало да трошите много за један. Истраживањем и узимањем у обзир ових фактора, може се пронаћи прави ласерски систем обележавања за вашу аутомобилску апликацију

Садржај

- Ево шта купувачи аутомобила треба да знају

- Дакле, Који су најновији напредак ласерског обележавања за аутомобилске поље

- Na šta bi kupci trebalo da obrate pažnju

- Савети за ефикаснију аутомобилску производњу са ласерским обележавањем Који су кључни разлози када се трансформише ваш процес како би се стекла конкурентна предност

- Где можете добити поуздане ласерске машине за обележавање за аутомобилску индустрију