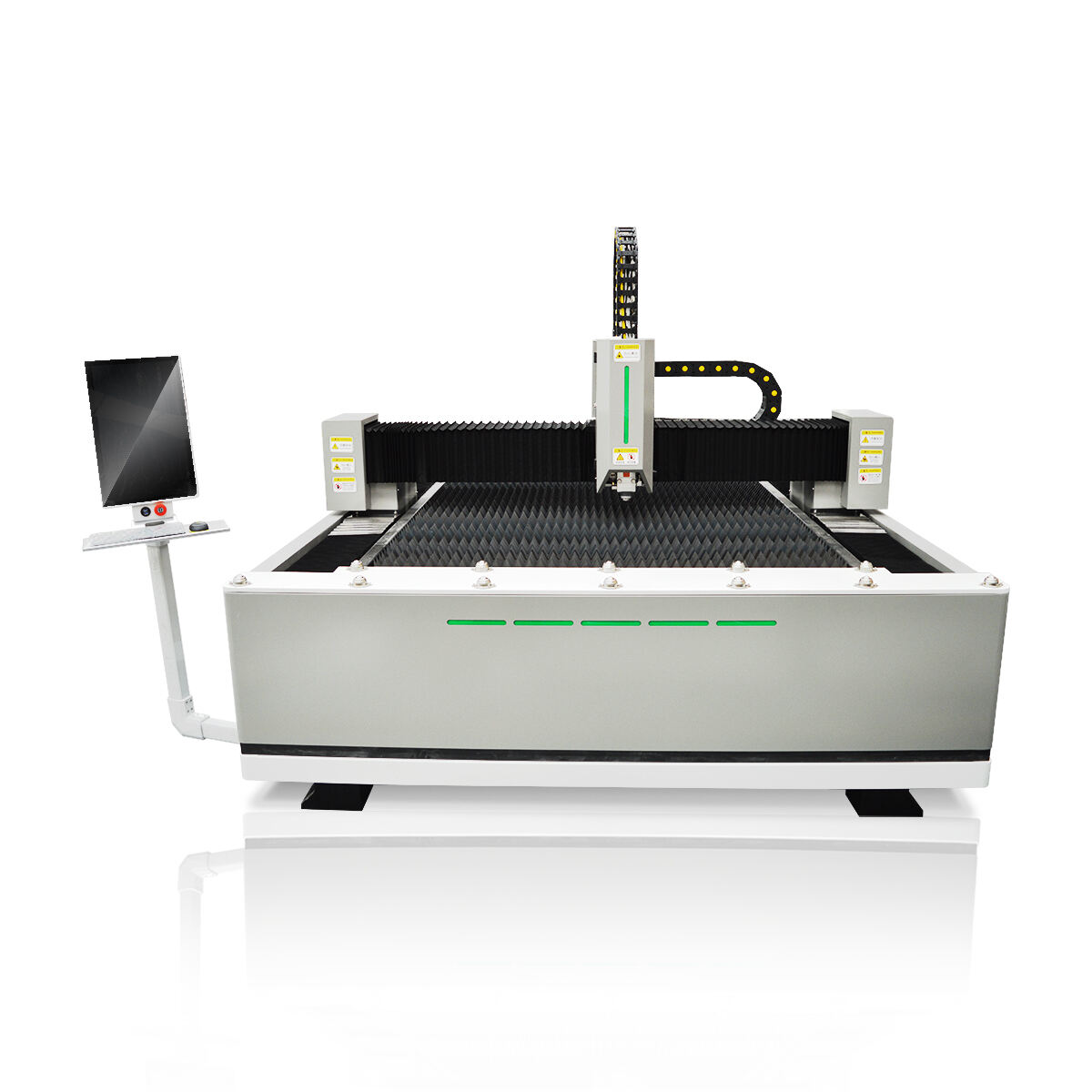

Laser Welding Machines are wonderful equipment that is used in many industries to weld metal parts together. They melt and fuse materials using a laser beam, which is an incredibly focused light. This process is quick, and accurate; hence it has found application in industries where high quality products are required. Laser welding machines are used in a variety of industries such as the automotive, aerospace and electronics industry. In car manufacturing, for example, they can fit parts together with incredible precision to ensure cars are safe and reliable. VOIERN supply high-quality laser welding machines which enable companies to enhance their production. Additionally, those looking for innovative solutions might consider the Split type laser marking machine for their operations.

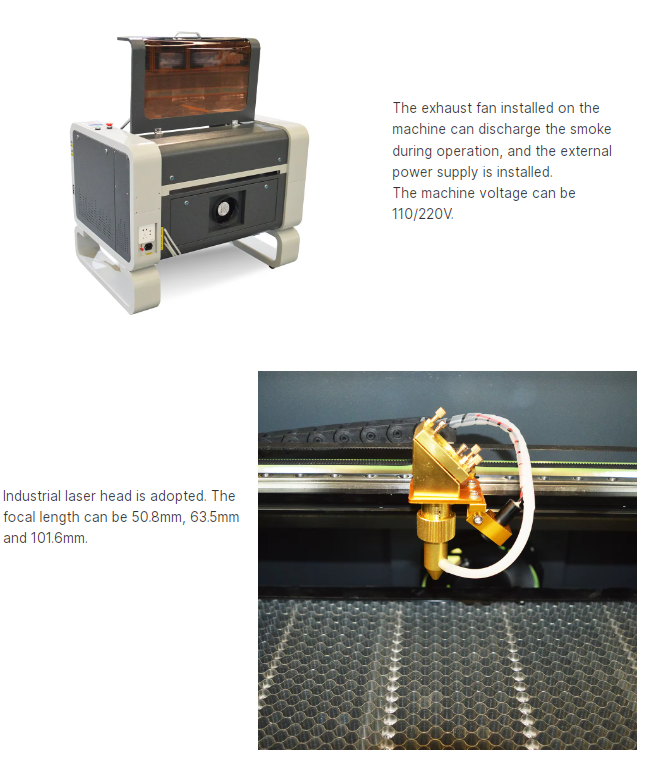

What are the Advantages of Laser Welding Machine for Your Business? The use of a laser welding machine can transform the way a company works. First, let’s talk about speed. Laser welding is significantly faster than other methods of welding, allowing businesses to create more products sooner. This assists in satisfying the customer needs on a prompt basis. And laser welding is very accurate. It is possible to make incredibly small and intricate welds, which diminishes possibilities of making mistakes. That means less waste — and more money in the bank. And, it is also clean process. Laser welding is not like some other welding methods, in which there’s a lot of smoke and slag. This will help maintain a clean and safe work environment. And with Voiern’s cutting-edge technology, the machines don’t need as much maintenance, saving businesses money and time. Customer satisfaction is also improved. People return for more with better product. Laser welding does this and can bond various kinds of metals that other methods have difficulty with. For instance, some companies cannot join aluminum and steel, while laser welding can. This creates new opportunities for companies to develop innovative products. All of these advantages mean that laser welding is a wise choice for businesses interested in developing and enhancing their company. For those exploring related technologies, the Laser engraving and cutting machine 9060 is another excellent option to consider.

How to Select the Direct Laser Welding Machine for Wholesale? With so many options of laser welding machines abound, it’s easy to get overwhelmed – but it doesn’t have to be that way. First, companies need to consider what they want. What kind of materials will they be working with? Various machines may work better with different types of metal. Voiern can provide different models of machines for a variety of materials. Next, consider the machine’s power. The greater the power of machine, the thicker material it can process and the more expensive it is. There’s a balance to be struck between power and cost. Another consideration is the features of the machine. Some laser welding machines also have sophisticated technology like automatic settings or intuitive control systems. All of these features are time-savers that can give a welder an easier time welding. And companies should consider the size of these machines, too. Sure, you might need a bigger machine for huge projects, but when you want something done fast and accurately (like on a smaller project) that smaller guy sure can come in handy! Finally, be sure to look up the manufacturer support. Voiern has an excellent customer service team that will answer your questions (and provide assistance) when you need it. Taking these aspects into account, any business can make the right choice to cater for its welding needs and ensure successful operations.

Laser welding machines are powerful devices that connect something together by emitting a beam of the concentrated light. But they also can be fraught with difficulty. One problem is the machine configuration itself. It could be the numbers for laser power, speed and focus are not adjusted well for such a materials. A weld can be weak if the power is to low. If it’s too high, I’m going to melt the material or introduce some sort of defects. To solve this problem, just read the Voiern user manual and don't ignore their advice for all sorts of materials.

There are times that the laser welding machines might not just be as you planned. Identifying these issues can save time and material. One of the standard problems which may be encountered is bad weld quality. Weak or Spotty Welds: If you see weak or otherwise poor weld quality, the laser's power may be set too high. First, verify the power level and speed. Ensure they’re designed to fit the type and thickness of materials you’ll be welding. Voiern machines can be accompanied by an extensive manual – that may aid to configure these parameters.

Finally, if there is any unusual noise from the machine, it means some internal components may have gone bad. Do not ignore these sounds! If the machine stops, refer to the user manual for causes and solutions. Voiern also provides customer support so if you need help just get in touch. Being informed about what can go wrong, and how to repair it will help a user take care of his/her laser welding machine.

Laser welding has advanced considerably in recent times, and there are a wide range of new features available by which wholesale buyers can be amazed. Among the most notable: ML-driven automation. Most of the new Voiern laser welding machines today are equipped with robotic arms that can automatically transport and position materials for a much higher degree of precision and more speed. This, in turn, enables businesses to make more high-quality welds in less time – and that means increased productivity.