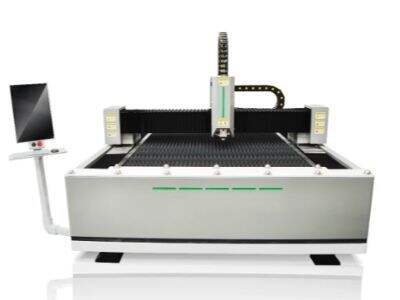

When shopping for a high power laser cutter for metal applications, the endurance and performance of your chosen machine is paramount. With it, a sturdy laser cutter can help you make beautiful things out of metal. Voiern is a label that's committed to producing high-quality machines. You’ll need a laser cutter that’s powerful enough to work with several varieties of metal, such as aluminum or stainless steel. With an excellent laser cutter, cutting/engraving/marking metal surfaces is a cinch. But which one should you choose? Now, let’s break down what to look for and how to compare features

What to Look for in a Reliable Metal Laser Cutting Machine

In choosing a laser cutter, the first thing to check is its power. The horsepower of the machine is typically an indication of how thick and tough a metal it can cut. Higher wattage is able to cut deeper metals faster. So, if you want to cut, say, 1/2-inch steel, use at least a 100-watt machine. Second, consider the amount of the cutting bed. This is where you deposit your metal. If you would like to slice big pieces, such a large cutting bed is also needed. Voiern’s laser cutters come in varying sizes so you can pick one that suits your requirements

Also, note the type of laser that’s being employed. CO2-cutters are the most popular and can cut through many materials. Fiber lasers are ideal for metals, but they cut faster and much more efficiently. It’s wise to consider the type of work you will do most frequently before making your choice

Another thing to look for is the longevity of the machine. See if the frame is made of sturdy material. A sturdy frame prevents a laser cutter from shaking while in use, improving the quality of cuts. Also, keep any eye out for great features such as a cooling system. A good cooling system ensures the machine runs well and can help it last longer

Tips for Comparing Laser Manufacturers to Choose the Best Option For Your Business

When it comes to comparing laser cutters, features really count. One key feature is speed. Some machines cut more quickly than others, which can be a real time-saver on larger projects. For instance, a speedier laser cutter can complete a project in hours rather than days. This is particularly useful in a high volume workshop

Don’t forget about the software that ships with the machine, either. User friendly software is easy to design and send projects to the cutter. With some machines, you can link up directly with a computer or laptop; others include built-in designs that range from elegant fonts to funky monogram shapes. The more alternatives you have, the more creative you can get

Next, check the cutting thickness. The thickness of the metal is also limited for laser cutters. And depending on what you do, you might need something that can cut off 1-inch steel or more. Voiern machines can accommodate multiple thicknesses, so you can choose the one that works best for your projects

And, of course, you can’t forget about safety features. The best laser cutters will never do something you don’t ask them to. Some machines even include enclosures that contain fumes and protect you while you work. This is essential for your health and safety, particularly when dealing with metals that can emit toxic fumes

When using laser cutters, particularly for projects that involve metal, learning these common troubleshooting topics is a must

One big issue is that the laser can lose its alignment. That is, the laser beam doesn’t hit its mark on the metal — resulting in a jagged and uneven cut. Ensure that you check and set alignment for your Voiern laser cutter of any kind to bypass this. Another common issue is overheating. Get the machine too hot, and it can stop working or worse yet, be damaged. To avoid this, just make sure that you have a cooling system. This may involve water-cooling the or letting the machine rest between cuts. The other problem is the materials are crap. The cuts are not necessarily clean if it's poor metal. Try to use good quality metal that is for laser cutting. Also, sometimes the code for the program that runs on the laser could be buggy or bad. This may cause errors in cutting. Be sure to stay updated with your software and test it for problems before starting a project. And lastly, they wear out over the long term. Some parts of the laser cutter, such as lenses and mirrors, can become dirty or damaged and compromise performance. A routine inspection and cleaning of these parts will help keep your Voiern laser cutter in good condition. Knowing these pitfalls, and how to avoid them, will help ensure your projects go smoothly

It can be difficult to find an inexpensive laser cutter that’s also good quality

The general thinking goes like this: You get what you pay for, right? Many people think that you have to put in a fair amount of money to buy a good machine, but that’s not always the case. First, do your research. Shop around and compare models. Voiern also provides a variety of machines that cater to various budgets. Sometimes second hand or refurbished models are just as good as new ones, but less expensive. Also, think about purchasing directly from the manufacturer or a reputable dealer. They might have promotions or discounts that can save you money. Another way to save is to join online groups or forums. These establishments also frequently post deals as well as advice about where to find budget machines. You can also inquire with other users about their own experiences using various models. This can prevent you from wasting any money on a machine that might not do the job for you. Search for reviews and feedback on the laser cutter you are interested in — focusing on performance and durability. And finally, don't overlook the cost of upkeep. A less expensive machine will probably require more repair, and those costs can mount over time. Voiern laser cutters are durable, so you will not worry about breaking down the machine very often if you choose to buy a good one. But with some patience and research, you can find a laser cutter that fits your budget without cheapening out on quality

If you need a laser cutter for metal that will be used in heavy use applications, there are some features to look for

What is the power of the laser you are looking for? Thicker metals are more easily cut with a stronger laser. Voiern has pinball machines in multiple power selections, allowing you to choose what suits your project. Another critical factor is the cut speed. The more quickly the machine is able to cut, the more projects you can finish in less time. But be cautious to never trade speed for the quality of the cut. You need speed and precision in equal measure. Material Handling – These machines ability to handle material is also very important. It ought to have the capacity to wrangle large sheets of metal without much effort. This involves sizing the working area available from the cutter. Also factor in the cooling solution. For heavy duty use, it is crucial that the machine has a reliable cooling system so it will not overheat during long cutting jobs. Also, ensure that the machine has good software that gives you control and makes it easy to adjust your settings. It helps you to get the perfect results in your metal projects. Voiern laser cutting machine is supplied with powerful software, you will enjoy dynamic output support. With these in mind, you can be able to ensure that your choice of the laser cutter would work great for heavy-duty metal uses as well as enable you perform amazing projects in general

Table of Contents

- What to Look for in a Reliable Metal Laser Cutting Machine

- Tips for Comparing Laser Manufacturers to Choose the Best Option For Your Business

- When using laser cutters, particularly for projects that involve metal, learning these common troubleshooting topics is a must

- It can be difficult to find an inexpensive laser cutter that’s also good quality

- If you need a laser cutter for metal that will be used in heavy use applications, there are some features to look for