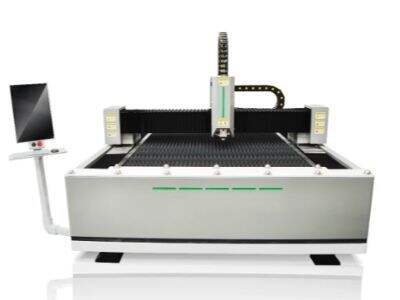

Medical Devices in the Healthcare Landscape There are multiple Life Science courses for a potential employee to take. They do much to aid doctors and patients. It’s crucial that these devices are safe and reliable. A handy tool that aids in this is the UV laser marking machine. The device uses a special light to leave marks on the surface of medical tools. The marks might contain important information such as serial numbers, bar codes and logos. A UV laser marking machine, such as the one by Voiern has benefits for manufacturers and offers a solution to increase medical devices quality

Advantages of UV Laser Marking Machines for Medical Equipment Makers

UV laser marking system is very suitable for the manufacture of medical devices. They can be used to mark on a variety of materials, including metals and plastics. This is significant as different devices are composed of various materials. For instance, surgical instruments could be stainless steel and the monitoring device might be plastic. The UV laser delivers a crisp, clearly mark with no material impact. This way, it is also possible that each device includes thereon the required information without damaging the surface. Harmful chemicals and inks are not necessary, either, which makes the process safer and cleaner. Voiern UV laser marking machines work fast, which is good for production accelerating. This means that devices can be produced in greater volume and faster. The machines are also incredibly reliable, so there are fewer errors. Fewer goofs also translates to companies saving money — and time. Furthermore, these machines are very low maintenance which is good for your bottom line. Manufacturers can concentrate on the production of equipment and need not be concerned with machinery defects. There is no pollution during the UV laser marking operation. No toxic fumes are emitted into the air or water. Which means that by using Voiern’s UV laser marking machines, not only are you good for business, but you’re also doing the planet a favor

The Role of UV Laser Technology in the Field of Medical Device Traceability

Traceability is such a big word, but it’s simply the ability to follow the trajectory of a product. Traceability is paramount in the medical field. If a device has a problem, doctors need to know where it came from and how many were made. UV laser marking greatly simplifies traceability. By the way, a single code or number can be like an idea with which one but multiple people work from different geographical locations. If a doctor wants to know more about a device, he or she can look up the code. This helps keep patients safe, because it makes it easier to remember devices when there is a problem. The marking is very distinct on Voiern’s machines. The marks are relatively permanent and will not degrade, even under difficult conditions. This translates into never fading or becoming unreadable. The mark will remain clear even if used repeatedly. Moreover complex designs can be realized by the UV laser marking method. This enables QR codes, which can convey quite a bit of information. Such codes can be scanned by patients and doctors, who can then quickly get access to key information about the device. That makes the information accessible to all. All in all, it is more convenient to manage the medical apparatus due to the application of UV laser marking technology

Why Is UV Laser Marking Suitable for Medical Materials

UV laser marking machines are an ideal option for coding medical devices. One of the coolest things about UV lasers is that they also play nice with sensitive materials. Special types of plastic or metal are often used in medical products, which can be damaged easily. Typical lasers might burn or alter the surface of these materials, but UV rays are another story. They emit short wavelengths of light that don’t produce a great deal of heat. What this means is that when the UV laser marks the device, it does not damage materials. This is critically important because medical devices must be safe for patients. If an appliance is damaged during marking, this can have consequences when the device is being used

Another benefit of UV laser marking is a very clear and precise mark. This is a major consideration with medical devices as the devices frequently require labels displaying important information, such as serial numbers, bar codes or logos. Nice and clear easily read marks ensure easy differentiation and tracing of each device for healthcare provider. With UV lasers, the markings can remain so long that they don’t fade? which is important for some devices that may sit in a warehouse before being used. Furthermore, UV laser marking is environmentally friendly. It doesn’t rely on damaging inks or chemicals that could harm the planet. This is yet another reason why Voiern and many others opt for UV laser marking of their medical devices. By applying this approach, they are able to develop a safe, high-quality product that is also environmentally friendly

Maximizing Your Production with UV Laser Marking Machines

When using UV laser marking machines in production, you should make a good plan. The first challenge is for companies to consider how they can organize their workspace so that the machines are used effectively. For instance, a visible layout with the machine within reach can be a time saver. Employees can easily grab the devices, take them to the machine, mark them and pass them along to the next step. That way the production line keeps flowing seamlessly

A second and important component of maximizing production is training the staff. Authentic Project As a worker, you should know how to correctly use UV laser marking machines. This is knowing how to dial the machine correctly for different materials and what settings work best for assorted mark types. Voiern provides training and advice so companies can get the most out of their machines. A well-trained staff can create quality marks more quickly and with fewer errors

Regular maintenance is also crucial. Maintaining the equipment also helps prevent breakdowns, which can disrupt production and add additional costs. Regular checks and cleaning could help the machines run better for longer. Last but not least, companies must be able to also monitor their production data. That includes checking how many devices get tagged, how long it appears to take, whether there are any problems. Companies can use this information to try to improve, and make their production even better by analyzing it. With these preparations, the use of UV laser marking machines can definitely increase production volume and help companies like Voiern produce high-quality medical devices

Where to Get the Best UV Laser Marking Machine for Medical Devices

It is important for companies that produce medical devices to find the right UV laser marking equipment. One of the best places to begin is by finding companies that focus on laser technology. Many of these companies also have a variety of machines that are ideal for various needs. "Make sure to select equipment specifically for medical use. This means that the machine will with all probability be able to print on a wide range of medical materials without damaging it

Voiern is an excellent choice if you need top-notch UV laser marking machines. They offer machines designed to adhere to the high standards required in medicine. You should also take into account the support and service included with a specific machine. A good company should provide training, maintenance and fast assistance if anything goes wrong. This is crucial because medical devices must be crafted with care, in safety

And buyers should read reviews and ask other companies how they liked working with particular machines. That can help them figure out which machines work well. Another thing you can do is visit trade shows or industry gatherings where different companies bring their products to market. This enables buyers to view the machines in person and ask questions. Last but not the least is reviewing your pocket. Though the lowest option might be tempting, it is better to opt for an enhanced performance UV laser marking machine at Voiern in a view of acquiring good results at later stage. With the proper tools, businesses can be sure their medical devices are safe and effective in how they are marked

Table of Contents

- Advantages of UV Laser Marking Machines for Medical Equipment Makers

- The Role of UV Laser Technology in the Field of Medical Device Traceability

- Why Is UV Laser Marking Suitable for Medical Materials

- Maximizing Your Production with UV Laser Marking Machines

- Where to Get the Best UV Laser Marking Machine for Medical Devices