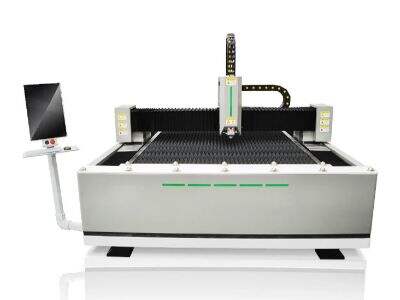

We live in a world of cars. They enable us to go to work, school and see friends. It’s a big job to build these cars. There’s no time for drag in the automotive business. It’s why so many car manufacturers rely on CNC fiber laser cutting machines, such as those available at Voiern. Image These machines are special cutting and shaping tools for metal car parts. They are key to how cars are built and in keeping things running smoothly

Why do automotive fabrication need to use CNC Fiber Laser Cutting Machine

CNC fiber laser cutting machine is super useful in cars making. They can make precision cuts through metal. So the parts all fit together really well, which is critical because even a small mistake can have big consequences down the line. “For instance, if something is too large or too small, it could malfunction, and that could be a hazard. CNC machines allow car manufacturers to cut parts into different shapes and sizes without wasting an enormous amount of material. It’s not terrible for the environment, either, because less waste is obviously better than more garbage. Added to which, these machines never get tired and can work all day, so they are great for keeping production moving quickly. Voiern’s machines are designed to do the dirty work of cutting high-strength metals, commonly used in car frames and other parts. This allows car companies to create safer and more reliable vehicles. Yet another cool factor about CNC fiber laser cutting is that it is able to accomplish super detailed patterns. Designers can also get creative and create parts that look great but are still strong

What are the advantages of CNC fiber laser cutting for automotive industry

There are many advantages to the application of CNC fiber laser machines in automotive. First, they save time. Because they cut so fast, car companies can produce more parts in less time. This allows them to get cars in the hands of customers more quickly. The second: These machines are astonishingly precise. The cuts are so clean that no (or very minimal) extra work is required later, which not only saves time but also money. Third, it can cost less to use these machines. They use less energy than older machines, so you won’t see your bills surge. Voiern’s CNC machines are super-computer-energy efficient, which is good for the company end it and our blue planet with big white swirls. Fourth, these machines aid in safety. Not only do they machine the parts to fine tolerances, so well that there will be fewer errors leading to issues in the cars. What this means is safer cars for everyone driving on the road. Finally, CNC fibers lasers are quite versatile. Designs can be quickly altered or new parts produced without firms having to invest in entirely new equipment. This agility is what enables businesses to remain competitive and to meet consumer demand. By and large, CNC fiber laser cutting machines are an important market for making cars better, cheaper, faster

How To Select The Suitable CNC Fiber Laser Cutting Machine for Automobile Industry

Choosing the right tools is critical when it comes to dealing in cars and other vehicles. The CNC fiber laser cutting machine is one of the greatest productions of the car industry. This machine is used to cut metal and other materials extremely accurately. But which kind is best for you? First, consider what type of material you will be cutting. Various machines can cut varying materials, from steel, aluminum and even plastic. Make sure the thickness of material you use can be accepted by machine. For instance, you may require a more powerful machine if you’re working with heavier metals

Now focus on the size of the machine. Some CNC fiber laser cutting machine are large, some are small devices. You should ensure that you have room in your workshop for the machine you select. And consider the size of pieces you will be cutting. If you are creating big parts for a vehicle, you need a machine that can easily hold them. An additional degree of complexity is due to the high speed of the machine. Time If you need to complete a large volume of projects, you will want an efficient machine that can cut fast but still maintain accuracy. Voiern provides high speed and precision machines, ideal for the fast pace demands of automotive manufacturing

Finally, do not forget to consider the cost. CNC fiber laser cutting machines may be costly, so you need to shop around and find one that suits your budget. But keep in mind that a bit more up-front can be a money-saver over time for a better machine. An expensive machine is likely to last and need less maintenance. Seek machines that have good customer support and warranties, so you can get assistance if something goes awry. By taking all of this into account, you can select the best CNC fiber laser cutting machine for your automotive needs that will make it easy to build great cars

What Makes CNC Fiber Laser Cutting the Best Option for Automotive Supply

There is an increasing demand for CNC fiber laser cutting in the automotive industry. There’s a few reasons for this. The laser cutting accuracy is unmatched by any other process. When producing car parts, it is crucial that every piece fits exactly. CNC fiber laser cutting machines They generate exact cuts that are needed to ensure all of your parts fit together properly. That means fewer mistakes and less waste, an excellent bang for the buck when considering time and resources

Another reason that a number of automotive suppliers like this method of cutting is fast it. Timing is of the essence in the automotive business. Suppliers must have their parts made in a hurry to avoid falling behind production schedules. CNC fiber laser cutting machines cut materials at a speed far greater than traditional methods. This allows suppliers to meet deadlines and satisfy their customers. Voiern machines are high speed cutters so that automotive suppliers can keep pace with the auto industry

Furthermore, CNC end fiber laser cutting is quite flexible process. That said, it can build all sorts of parts, ranging from small components to bigger structures. Automobile suppliers frequently have to make different kinds of parts for different models of cars. And with a CNC fiber laser cutter, they can simply adjust the settings on the machine to cut a variety of shapes and sizes without changing out any tools. This flexibility allows suppliers to be more easily responsive to market changes

Finally, CNC fiber laser cutting can also be greener. The method is more sustainable than many other cutting processes. This is due to the fact that the laser cuts very accurately, so there’s less waste material. In this day and age, most companies want to be more sustainable and CNC fiber laser cutting is one way to help. As a whole, the precision, speed, flexibility and environmentalist nature make CNC fiber laser cutting has become the best alternative for a lot of automotive suppliers

Which New CNC Fiber Laser Cutting Techniques are Revolutionising the Automotive Sector

The automotive sector is constantly evolving and growing, and one of the largest leaps forward are due to CNC fiber laser cutting technology. These innovations are enabling companies to produce better cars more efficiently. Among the most appealing advances is the ability to cut even faster and more accurately. CNC fiber laser cutting machines can process materials at high speeds and with a high level of accuracy using new technology. That translates into faster time to manufacture for manufacturers, which is bread and butter in today’s speedy automotive market

Another good advancement is the ability to cut varied materials without having to change the machine all that much. On older machines, that often required off sizes or even different tools for different materials. However, it’s not the same case with current generation CNC fiber laser cutting machines because you can easily use various materials such as steel, aluminum and plastics. This flexibility makes it possible for car manufacturer to produce parts more varied without wasting time or lose quality. This is where Voiern stands out; their very own machines are easily able to handle a variety of materials

On top of this, the goalposts have shifted in software too. New software tools allow for better planning of cuts and reduce waste, making more efficient use of material. This intelligent software can even help design parts to make them simpler to cut — saving time and money. Automakers can develop more intricate patterns that were impossible before, adding style and performance to cars

Finally, automation and robotics have been introduced to CNC fiber laser cutting machine. This means that machines and robots can now collaborate to make cutting faster, but rationalised. Robots can load and unload materials while the laser cutter is running, shortening the time to make parts. It’s not just a time-saver, however, but also a safety measure for the workforce. These advancements are still unfolding and impact of which will have a major say in how the car industry will evolve to become smarter and more efficient

Table of Contents

- Why do automotive fabrication need to use CNC Fiber Laser Cutting Machine

- What are the advantages of CNC fiber laser cutting for automotive industry

- How To Select The Suitable CNC Fiber Laser Cutting Machine for Automobile Industry

- What Makes CNC Fiber Laser Cutting the Best Option for Automotive Supply

- Which New CNC Fiber Laser Cutting Techniques are Revolutionising the Automotive Sector