Лазерлі ембоссинг машиналарымен өндірістікте өнімшілікті арттыру

Лазердық жазбалау машиналарының кезіндеғі сабақтаудағы rolі

Дәлдік және тезілік: үстік производительность өндірістері

Точтік сабақтау саласында лазерлік естеңгейтін машиналар технологиялық дамуға әділет ретінде табыс жасайды. Олар 0,01 мм-ге дейінгі толеранспен артықсыз точтікке ие болып, өндірістік қабілеттерінің сапасын арттырады. Бұл точтік функционалдықты және көркемшілікті әсер етуі мүмкін болатын салаларда маңызды. Мазмұнда, олар традиционалды естеңгейтін әдістерден 100 рет артық жылдамдықпен істерлеуге мүмкіндік береді. Бұл мүмкіндік өндіріс температураларын арттырады және бастапқы уақыттарды кемітеді, бизнес қажеттілерін жылдам және пайдалы түрде қанағаттандырады. Өндіріс сызықтарына интеграцияланғанда, лазерлік естеңгейтін машиналар сапалық қорытындылар мен практикалық зерттеулер бойынша 20-30% шекте производительностьті арттырады. Лазер технологиясын қабылдау - бәсекелердің конкуренттік қабілетін сақтау мақсатында стратегиялық қадам.

Салалар арасындағы материалдық көптігілік

Лазердік жоба машиналарының белгісі – бұл материалдарға қатысты ешқандай мағаналықты әсер етпейтін көлемі, бұл сectors-тардың көпшілігі арқылы мəншік болуын қамтиды. Олар әртүрлі материалдармен жұмыс істей алатын, одан кейінгі тапсырмаларға дейінгі деректерге сай, олар қырық, пластик, метал және әдетте стекло кез келген материалдармен жұмыс істей алады. Бұл материалдарға қатысты кең көлемді қабілеттері бизнеслерге берілген таңдауларды қосуға мүмкіндік береді, особынша зур жобалаудың қажеттілігі бойынша ювелирлік және авто индустрияларында. Зерттеу бойынша, бұл қабілеттен пайдаланатын өндірісшілер өз продукттерінің кеңейтуі мен жаңа пазарларға шығу арқылы әсерлі өсу көрсеткіштерін көрді, себебі олар өзгеретін қызметкерлердің қажеттіліктерін қанағаттандыруға болады. Бұл адаптивдық не тек бизнес пазардағы орналасуын қалыптастырады, бірақ шығысқа шолу жасауға қатысты қызметкерлердің шегіндеғі қажеттіліктерін де қанағаттандырады.

Лазер шегімдік машиналарының дәлдігі мен жылдамдығын пайдалану арқылы, сонымен қатар әртүрлі материалдардағы гибдігі бойынша, модерн сабақтау еңбекшілігі еңбасы не тек тиімділікке өтініш көрсетеді, бірақ қалпына айту алатын. Бұл трансформациялық технология жаңа стандарттарды қалаушы және бизнесге алдын-ала кездесетін ынтымақтық пен дәлдікпен жасау және персоналдау мүмкіндіктерін ашып отырады.

Сабақтау еңбекшілігінің тиімділігін арттыратын негізгі қасиеттер

Қатысты шығын беру үшін қалыптастырылған оптикалық системалар

Қазіргі лазерлік жобақы машиналары әдістік оптикалық жүйелерді пайдаланады, мысалы, XY галванометр сканируоты, барлық сабақтардағы жобақы сапасын тұрақты болуын қамтамасыз етеді. Бұл әдістік оптикалық жүйелер өсірмей-шығын азайтуға көмектеседі, ал энергиялық қызметкерлігін арттырады, сонымен қатар эксплуатация құпияларын азайтады. Аспаптық деректер бойынша, осы әдістік жүйелерді қолданатын компаниялар өнімдердің бірдейлігінде 15% арттыру туралы хабарлауды жасайды. Тұрақты дәлдікті қамтамасыз етуге мүмкіндік беру арқылы, осы машиналар сапа қызметінде және өндірістік процестердегі ырыс сапасын сақтауда маңызды роль атқарады.

Автоматтандырылған жұмыс ағынын интеграциялау

Лазердік шығарма машиналарын табиғатты аутоматтандыру системаларымен біріктіру, өзгеше операциялардың орын алmasын taқтарady, қол еңбекпен тигізуді және адам кемелерімен байланысты қателерді азайтуға көмектеседі. Бұл аутоматтық процестік тездікті 25% -ге дейін кемиді, бизнесдер қажеттілерге сәйкес тез қайтару мүмкіндігін арттырады. Көптеген өнеркәсіптік зерттеулер лазердік шығарма аутоматтандыру системасын қолдану арқылы жанархана өнеркәсіптік производительностьді көбейтуге көмектескенін көрсетеді. Процессілерді ықшамдау арқылы компаниялар жұмыс іzmін effiциенттілігін арттыра алады және көмектеседі рахметтілікке.

Ұзақ өмірбап компоненттері уақытты азайту үшін

Лазерлік жоба машиналарындағы ұзақ талдауға ие компоненттер кем деген соңғы сәтте техникалық обслуживанға және төменгі түрде тез-тең бекітілмейтін шағын уақыттарға мүмкіндік береді, машиналарды ұзақ уақытта артқаланбасыз жұмыс істеуге мүмкіндік береді. Қабілетті компоненттер емдеу және емдеуді кемітуге көмектеседі, олар машиналардың жылдамдығы мен достыққа непосредственно әсер етеді. 2023 жылғы өнеркәсіптік аналитиктердің отчетінше, ұзақ талдауға ие компоненттермен жабдықталған машиналар тез-тең бекітілмейтін шағын уақыттарды 40%-ға дейін кемітуге болады. Бұл операциялық достық өнеркәсіпшілерге қатысты өнімдердің деңгейін сапалы қалдыруға мүмкіндік береді, барлық процестердің жалпы қызметкерлігін жоғарылауға мүмкіндік береді.

Voiern Лазерлік Жоба Машиналары: Продукт Түсіндірме

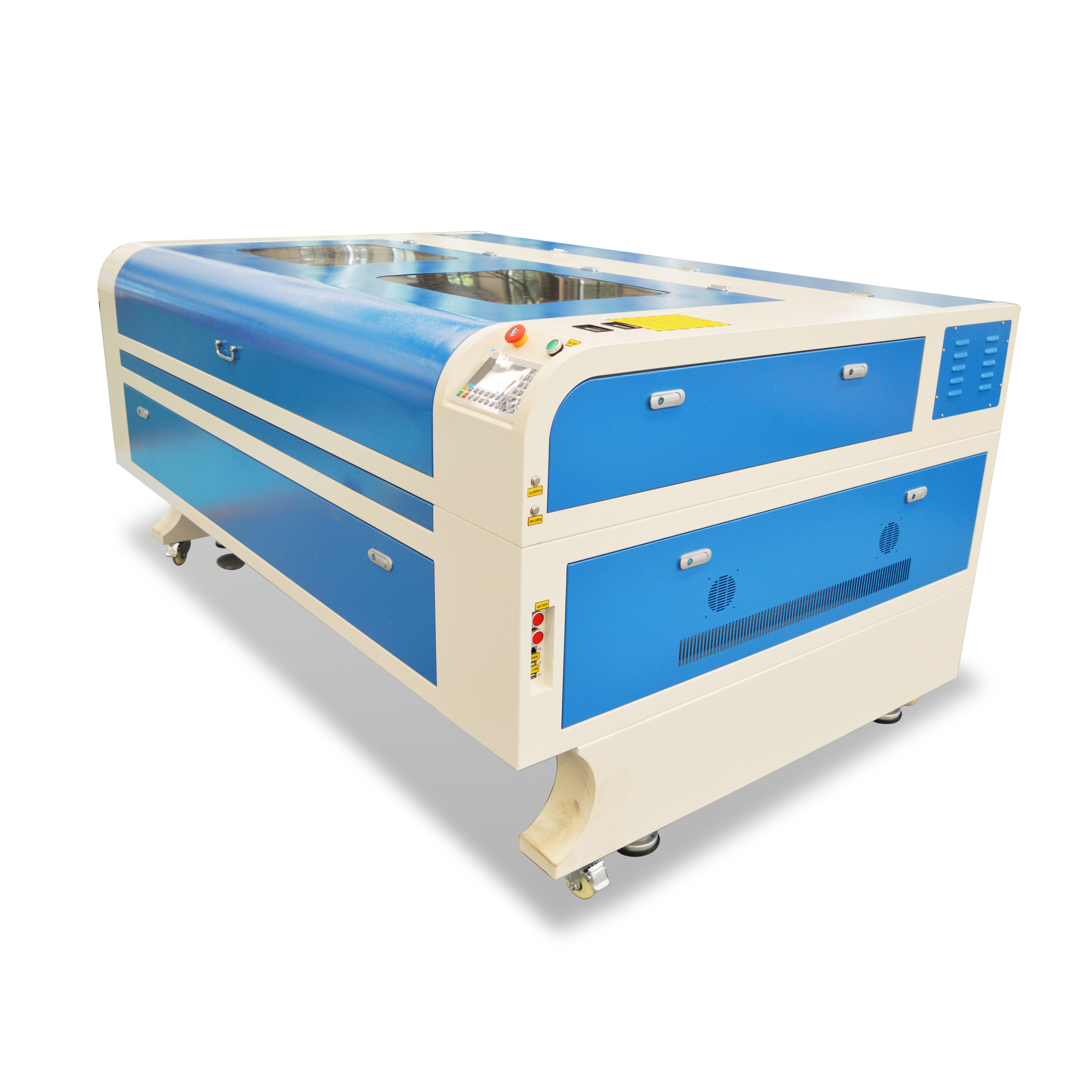

Лазерлік Жоба және Кесу Машинасы 1310: Өзге Жетістік Платформа

Лазердық жобаушы және кесу машинасы 1310 біртекте сапасындағы дәлдік үшін дизайн lanг алатын, бұл оны жемістерге жобау сияқты тоннайым қолданбалар үшін ідеалды етеді. Оның қолдауы қолайлы, операторлар өндіріс сериясын тез шығаруға мүмкіндік береді, производительностьлерін оптималастырады. Сатып алудың деректері бойынша, бұл модел өзінің алдындағыларға салыстырғанда, қызық технологиясына сенімді болмаған 25% маңыздылық көрсетті.

Лазердық Жобаушы және Кесу Машинасы 1530: Улттық форматтағы өңдеу

1530 моделі үлкен форматтың ішінде өңдеу арқылы табысты, бұл сағының жасау және мебель өнімдерін өндіру саласы үшін маңызды хасият. Оның қолдасты софтуер шешімдері дизайндау процесін қысқартады, тапсырмаларды концепциядан аяқтауға дейін ыңғайлағандағы міндеттерді орындаған. Базар анализі бойынша, 1530 сияқты үлкен форматтық машиналар өнімдердің еңбек іс-шарын 30% арттыра алады, бизнеслерге кеңейтілген проекшелерді тиімді түрде орындауға мүмкіндік береді.

Лазер Еңбердеу және Кесу Машыны 1610: Автоматтық Тауып Алу Сistemасы

1610 моделі атомалық беру жүйесі бар, ол өзіндік іс-шаралардың күштілігін маңызды түрде арттырады, сұрыптауға риза болмайтын жұмыстың жүргізілуін мүмкін етеді. Бұл автоматика үлкен көлемдегі шаруашылық мәселелер үшін маңызды пайдасы бар, өйткені қолмен жүктеуден қате тапсырмаларға қатысты шағымдау құнын кемиді. Реттелгендер ұсыныстарына сәйкес, автоматика мүмкіндіктеріне сәйкес өзіндік іс-шаралардың күштілігінің артуы бойынша қаншалықты 40% қанаттылық артты.

Лазердік жазбалау және қиыну машинасы 3020: Кіші көлемдегі өнімдердің индустриялық шешімі

3020 моделінің кіші өлшемді саналы дизайні оны кіші жерлерде қуанышты қоюға рұқсат етеді, бірақ қызметтерден қайта қолдануды қалаймыз. Бұл малдастық пен орташа бизнесге үйлесімді. Оның өлшеміне қарамастан, ол ырыстап алатын функциялармен тигізген және әртүрлі материалдардың түрлері мен қалыптарын басқару мүмкіндігі бар. Кіші бизнесдерге сай қолданба деректері бойынша 3020 моделі бірінші жылында сертификаттық қайта қолдануды қосымша етеді, сонымен қатар оның кіші операциялар үшін қиындықсыз және қажетті болуын көрсетеді.

Продуктивдылықты арттыратын қолданбалар

Трассировка үшін өзгертілген қисыр белгілеу

Өзгешең бөліктерді белгілеу өнімдердің кез келген уақытта табысыздығын арттырады, бұл ушбу жобалар мен автокөбейгі салалары үшін маңызды. Бұл салалар строгтық нормаларға сай есептеледі, олар бірлік компоненттердің барлық жылындағы өмір кезеңдері boyынша дәл өткізілетін табысыздықтарды талап етеді. Лазер белгілеу әрекеттері тұрақты белгілер береді, олар экстремалды шарттарға қарсы қарым-қатынасты ұстауға мүмкіндік береді, бұл белгілерді уақыт бойы сақталуы мен көрінетін болуын қамтамасыз етеді. Саладан тыс жариялатын деректер білдіреді, трассировкалық белгілеу системасын қолданатын компаниялар қызметкерлердің сапасын тексеру қателерін азайтуға мүмкіндік береді, бұл сапалық және нормаларға сай болуға негізделген.

Тез прототиплеу мүмкіндіктері

Лазердік жоба машиналары дизайнерлерге дизайндарын қайта қамтамасыз ету және оларды жоғарылауға мүмкіндік береді, сондықтан концепциядан бazarға шығу аралығы тездейді. Бұл қабілет сатып сатудағы секторларда, мүшкин, коммерциялық мувафаққиятқа әсер ететін уақыт факторына қарағанда маңызды. Секторлік зерттеулер бейнелерге ашық өңдеу құралдарын пайдаланатын компаниялардың өңдеу циклдерін 50%-ға дейін кемітуге болады деп көрсетеді, бұл әдетте үлкен конкуренттік үстем береді. Бұл қабілет сапарын қосымша ресурстарды қолданудың әмбебаптылығын арттырады.

Жиі тапсырыс өңдеу стратегиялары

Жылдамдық пен өнімділік лазер-engraving машиналарымен жұмыс істеу арқылы келесі плюстарға ие болады, олар компанияларға өзара әртүрлі өнімдерге деген талаптарды жеткізу үшін мүмкіндік береді. Осы машиналарды стратегиялық түрде қолдану арқылы ұйымдар сабақ-жобаларын ыңғайлауға, әлеуметтік өнімдерді үлгілеудегі уақыт пен жұмысшы ресурстарын кемітуге мүмкіндік табады. Үлгілеу нәтижелері бойынша лазер-engraving технологиясын қолдану арқылы үлгілеу уақыты 35% -ке дейін кеміді. Бұл өнімділікті арттыруға және ресурстарды ыңғайлауға мүмкіндік береді, бұл да үлкен көлемде шығаруға жол ашады.

Өнім қызметкерлігіне қатысты ROI анализі

Бірлік құнын кеміту есептері

Бірлік құнына қатысты төменшімісті түсіну, лазер енгізу технологиясын өнер саласында пайдаланудың финанстық нәтижелерін бағалау кезінде маңызды. Лазер енгізу аппараттары өндіріс құпияларын айналатын жағдайда өнімдер құнын қалай төмендетеді деп шығындар көрсетеді. Тtéоретикалық зерттеулер бойынша олардың бірлік құнын 15% дейін төмендетуге мүмкіндік беретіні анықталды, себебі олар материалдық отбасы мен қолданбаған материалдарды кемиді. Бұл өзінде көптеген сақтандыруларға және өндірістік саладағы конкуренттік мүмкіндіктерге айналады. Кеңесберушілер динамикалық пазар situation-да конкуренттік мүмкіндікті сақтау үшін осы деректерді мониторингдеу керек деп айтады.

Қамтамасыз ету экономикасы мен сыртқы қызметтер

Лазердік бейне жобалары арасындағы техникалық қызметтер мен субподрядтың экономикасын бағалау – өндірістік компаниялар үшін кеңес беретін шешім. Бастапқы уақытта субподряд ең соңғы тәсіл сияқты көрінсе де, ол кез келгенде ұзақ мүдdeгі қаржылық заттарға өтеді және маржаға теріс әсер етеді. Керісінше, лазердік бейне машиналарының ірі өндірістік компанияларға мәліметтердің сапасын және кездесу уақытын басқарудың мүмкіндігін береді, мүştəрилердің қанаттарын арттырады. Қошықтағы бағалаулерге негізделген дәлелдер көрсетеді, субподрядтан ішкі бейнеге өту арқылы компаниялардың маржасы 20%-ға артады. Бұл стратегиялық ие болу қандай тәсілмен компанияның жеке жолына және операцияларының жалпы қызметкерлігіне әсер ететінін көрсетеді.