Kluczowe czynniki do rozważenia przy zakupie maszyny do cięcia laserowego wtryskowej

Zgodność materiałów i zakres zastosowań

Metale kontra niemetale: zrozumienie ograniczeń cięcia

Wszechstronność maszyn do cięcia laserem światłowodowym przejawia się w ich zdolności do cięcia różnych materiałów, jednak istnieje wyraźna różnica w ograniczeniach cięcia przy porównywaniu metali z niemetalami. Metale takie jak stal i aluminium są idealne dla laserów światłowodowych ze względu na ich gęstość i właściwości odblaskowe, co umożliwia precyzyjne, czyste cięcia. Z drugiej strony, niemetale, takie jak tworzywa sztuczne i drewno, stanowią wyzwanie: długość fali laserów światłowodowych nie jest odpowiednia dla tych materiałów, a próba ich cięcia często skutkuje latającymi odłamkami, co może prowadzić do uszkodzenia sprzętu. Ponadto lasery światłowodowe doskonale sprawdzają się w cięciu metali odblaskowych, takich jak miedź i mosiądz, w obszarze, w którym inne typy laserów mogą zawieść. Według statystyk branżowych materiały takie jak stal nierdzewna, stal miękka i aluminium są najczęściej przetwarzane przy użyciu laserów światłowodowych. Maszyny te wyróżniają się w motoryzacji, lotnictwie i elektronice, gdzie precyzja i szybkość mają kluczowe znaczenie.

Możliwości obsługi wielu materiałów

Solidna wszechstronność maszyn do cięcia laserem światłowodowym pozwala im obsługiwać szeroką gamę materiałów, co znacznie usprawnia procesy projektowania i produkcji. Na przykład w branżach wymagających częstych zmian materiałów, takich jak elektronika i motoryzacja, ta możliwość znacznie usprawnia linie produkcyjne. Postęp technologiczny umożliwia teraz maszynom płynne przechodzenie między różnymi typami materiałów, takimi jak metale i niektóre tworzywa sztuczne, bez konieczności rozległych zmian konfiguracji. Studia przypadków w produkcji wykazały, że włączenie możliwości obsługi wielu materiałów może prowadzić do skrócenia ogólnego czasu i kosztów produkcji, a tym samym optymalizacji linii produkcyjnych. Te postępy technologiczne, w tym ulepszone systemy oprogramowania i zwiększona adaptowalność laserów, ułatwiają płynne działanie i automatyzację zwiększającą wydajność. Ta adaptowalność nie tylko minimalizuje przestoje, ale także sprzyja innowacyjnym rozwiązaniom produkcyjnym w różnych sektorach przemysłu.

Rozważania na temat mocy lasera i efektywności energetycznej

Dopasowanie mocy do grubości materiału

Zrozumienie prawidłowej mocy dla grubości materiału jest kluczowe dla uzyskania optymalnej wydajności lasera i zminimalizowania odpadów. Różne materiały wymagają określonych ustawień mocy, aby zapewnić czyste cięcia i wydajne operacje. Na przykład skuteczne cięcie stali o grubości ¼ cala może wymagać około 4 kW mocy, podczas gdy cieńsze materiały mogą wymagać mniej. Niewłaściwe ustawienia mocy mogą prowadzić do cięć poniżej normy, co skutkuje zwiększonymi stratami materiału i nieefektywnością operacyjną. Wykorzystanie odpowiednich ustawień mocy nie tylko zwiększa precyzję cięcia, ale także wydłuża żywotność maszyny, zapobiegając niepotrzebnemu obciążeniu. Wykresy lub diagramy przedstawiające wymagania dotyczące mocy w stosunku do grubości materiału mogą służyć jako niezbędne narzędzia dla operatorów poszukujących szybkich i dokładnych ustawień.

Analiza kosztów na cięcie przy użyciu systemów sprężonego powietrza

Ocena obliczeń kosztów cięcia w operacjach laserowych jest niezbędna, szczególnie w przypadku włączania systemów powietrza wysokociśnieniowego. Systemy powietrza wysokociśnieniowego mogą znacząco wpływać na koszty operacyjne ze względu na ich zdolność do utrzymania wydajności przy niższych kosztach. Na przykład stosowanie systemów powietrza zamiast tradycyjnych gazów może obniżyć wydatki operacyjne, a jednocześnie potencjalnie poprawić jakość cięcia. Dane porównawcze porównujące tradycyjne metody z systemami wysokiego ciśnienia wskazują, że systemy powietrza zapewniają bardziej opłacalną alternatywę przy zachowaniu jakości wyjściowej. Scenariusze, w których systemy powietrza są doskonałe, często obejmują niższe zużycie energii, co przekłada się na niższe koszty operacyjne, zwiększając ogólną wydajność operacji cięcia laserem światłowodowym.

Komponenty inżynierii precyzyjnej

Znaczenie szwajcarskich głowic laserowych i silników serwo

Szwajcarskie głowice laserowe odgrywają kluczową rolę w osiąganiu precyzyjnych cięć, znacząco wpływając na jakość produkcji w systemach laserów światłowodowych. Te specjalistyczne głowice laserowe są zaprojektowane tak, aby zapewniać doskonałą jakość wiązki, co przekłada się na czystsze cięcia i mniejsze straty materiału. Integracja z serwosilnikami usprawnia proces cięcia, zapewniając szybsze i dokładniejsze operacje. Serwosilniki zapewniają precyzyjną kontrolę nad ruchami, optymalizując interakcję lasera z materiałem. Dane branżowe pokazują, że systemy ze szwajcarskimi głowicami laserowymi i serwosilnikami przewyższają tradycyjne konfiguracje pod względem wydajności i wskaźników jakości. Ta precyzyjna kombinacja inżynierii jest niezbędna dla firm, które chcą utrzymać wysokie standardy w procesach produkcyjnych, szczególnie w takich dziedzinach jak lotnictwo i motoryzacja, gdzie precyzja ma pierwszorzędne znaczenie.

Systemy szyn prowadzących zapewniające powtarzalną dokładność

Systemy szyn prowadzących są niezbędne do zapewnienia dokładności i powtarzalności w operacjach cięcia laserowego. Stanowią kręgosłup maszyny, oferując stabilność i precyzję podczas cykli produkcyjnych. Wysokiej jakości szyny prowadzące zapewniają, że laser utrzymuje swoją pozycję i wyrównanie, co jest krytyczne dla uzyskania spójnych wyników. Słabe systemy szyn prowadzących mogą prowadzić do odchyleń w ścieżce cięcia, wpływając na jakość produktu końcowego i marnując cenne materiały. Testy producentów wykazują, że solidne szyny prowadzące przyczyniają się do długowieczności maszyny, zmniejszając potrzeby konserwacyjne i koszty operacyjne. Branże takie jak produkcja urządzeń medycznych, w których precyzja jest nie do negocjacji, czerpią duże korzyści z doskonałych systemów szyn prowadzących. Lepsze wyniki w takich sektorach podkreślają znaczenie inwestowania w wysokiej jakości komponenty do systemów laserowych.

Wsparcie operacyjne i integracja oprogramowania

Możliwości systemu sterowania Empower

Aby zmaksymalizować potencjał maszyn do cięcia laserem światłowodowym, nie można przecenić roli zaawansowanych systemów sterowania. Systemy te są projektowane z przyjaznymi dla użytkownika interfejsami, które upraszczają obsługę i zwiększają precyzję zadań cięcia. Integracja zaawansowanego oprogramowania pomaga w optymalizacji ścieżek cięcia, co prowadzi do skrócenia przestojów i poprawy wydajności. Na przykład wiele rozwiązań programowych dla maszyn do cięcia laserem światłowodowym oferuje automatyczne aktualizacje, które nieustannie udoskonalają proces cięcia w oparciu o analizę w czasie rzeczywistym. Ponadto integracja tych systemów z istniejącymi konfiguracjami produkcyjnymi może usprawnić operacje, zapewniając płynne przejścia między przepływami pracy i redukując wąskie gardła operacyjne.

Wymagania szkoleniowe i protokoły konserwacyjne

Szkolenie jest kluczowe dla operatorów, aby zmaksymalizować potencjał maszyn do cięcia laserem światłowodowym. Wykwalifikowani operatorzy są niezbędni do utrzymania wysokiej wydajności i uniknięcia kosztownych błędów spowodowanych niewystarczającym szkoleniem. Universal Tool & Engineering podkreśla znaczenie szkoleń i wsparcia na miejscu, co znacznie zwiększa biegłość operatora. Ponadto przestrzeganie rygorystycznych protokołów konserwacji ma kluczowe znaczenie dla długowieczności i optymalnej wydajności tych maszyn. Najlepsze praktyki obejmują regularne kontrole podzespołów maszyny i terminowe aktualizacje oprogramowania do cięcia. Badania wykazały, że firmy, które inwestują w kompleksowe programy szkoleniowe dla swoich operatorów, odnotowują znaczny wzrost wydajności produkcji w porównaniu z tymi, które tego nie robią. Jest to zgodne z wynikami raportów branżowych, które podkreślają znaczenie przeszkolonego personelu w osiąganiu maksymalnej wydajności operacyjnej.

Polecane rozwiązania do cięcia laserem światłowodowym

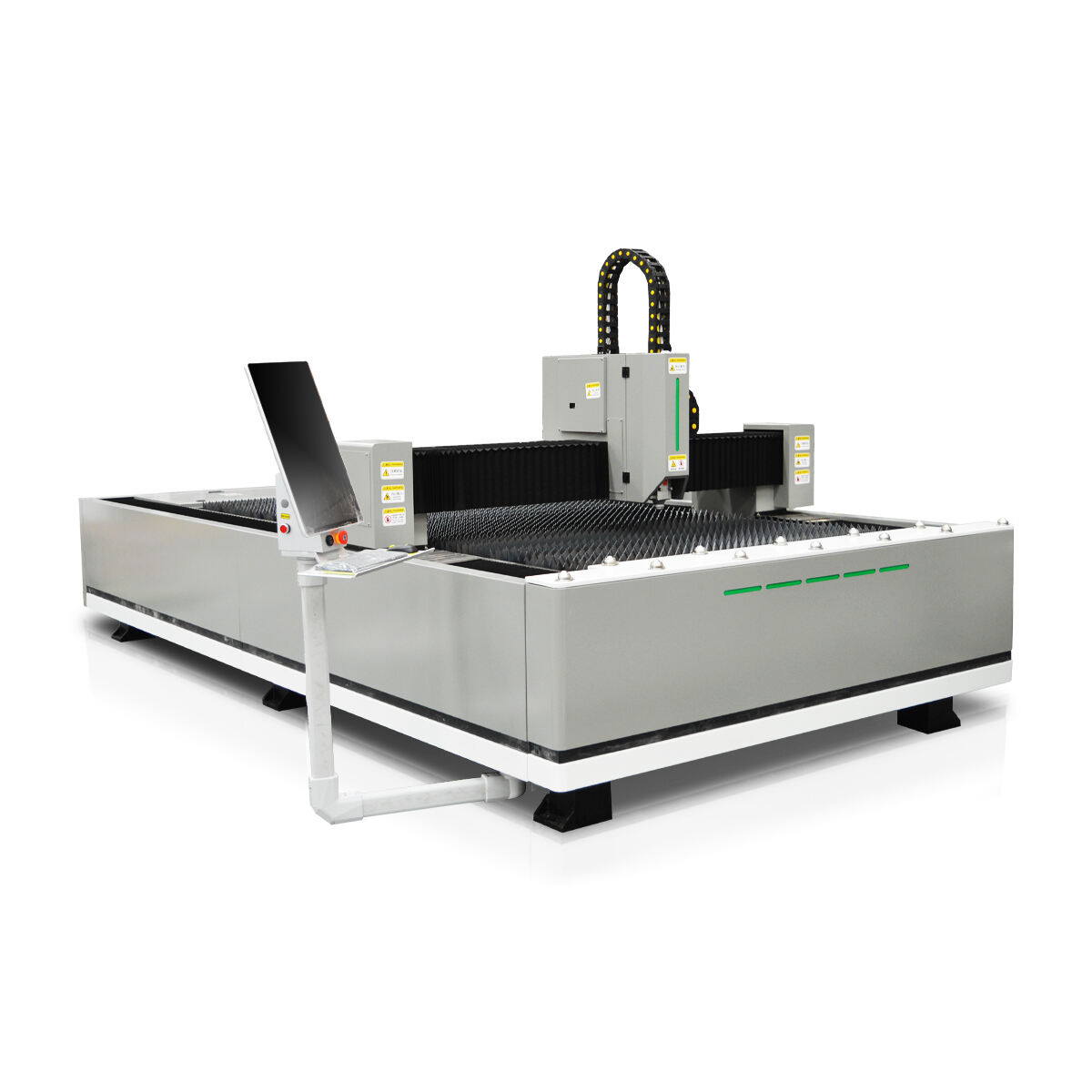

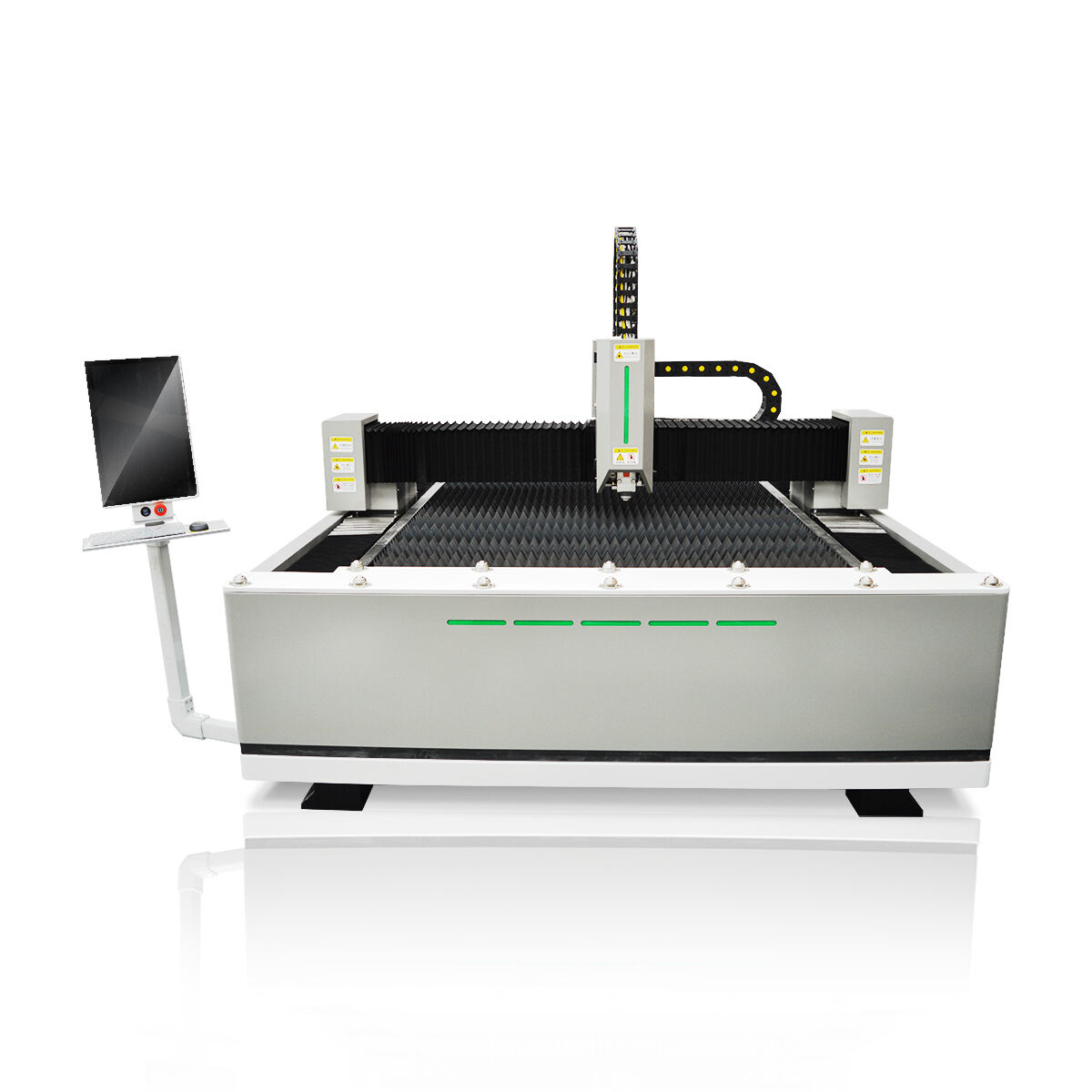

WR 1530 Maszyna do cięcia laserowego typu fiber: wysokowydajna precyzja

The Maszyna do cięcia laserowego włókien wr 1530 wyróżnia się wyjątkową precyzją przy dużej prędkości i jest kluczowym narzędziem w różnych zastosowaniach w branży obróbki metali. Ta maszyna szczyci się specyfikacjami, które zapewniają imponującą prędkość, osiągając tempo cięcia kilku metrów na minutę z niezmienną dokładnością. Jej konstrukcja umożliwia cięcie szeregu materiałów metalowych, od stali nierdzewnej po płyty tytanowe, co czyni ją wszechstronną w przypadku wielu projektów. Opinie profesjonalistów z branży podkreślają jej doskonałą wydajność, a klienci chwalą WR 1530 za bezproblemową obsługę skomplikowanych projektów. Porównując WR 1530 z innymi modelami na rynku, wyłania się jako faworyt ze względu na połączenie zaawansowanej technologii i przyjaznych dla użytkownika funkcji.

Maszyna do cięcia laserem światłowodowym 1530: zwiększona wydajność produkcji

The Maszyna do cięcia laserowego włókien1530 jest zaprojektowany, aby znacząco zwiększyć wydajność produkcji, co czyni go nieocenionym atutem dla każdej operacji produkcyjnej. Ta maszyna łączy wysoką wydajność z opłacalną pracą, wykorzystując innowacyjne technologie w celu zminimalizowania zużycia energii przy jednoczesnej maksymalizacji wydajności. Firmy inwestujące w ten model mogą spodziewać się znacznego zwrotu z inwestycji (ROI) dzięki jego szybkim operacjom i możliwościom precyzyjnego cięcia, które zmniejszają marnotrawstwo materiałów i usprawniają przepływ pracy. Dzięki najnowocześniejszym funkcjom zintegrowanym z tą maszyną, takim jak zaawansowane oprogramowanie i automatyzacja, sprawnie obsługuje ona zadania, które w przeciwnym razie wymagałyby znacznej pracy, optymalizując w ten sposób całą linię produkcyjną.