Discover the Future: Fiber Laser Welding Machines with Smart Cooling Systems

How Smart Cooling Systems Transform Fiber Laser Welding

Enhanced Precision Through Thermal Control

Smart cooling systems play a crucial role in maintaining optimal temperatures during the fiber laser welding process, effectively reducing thermal distortion and enhancing weld quality. This precise thermal control significantly enhances the predictability of weld outcomes, resulting in higher consistency in production. Furthermore, these systems lower operating temperatures, reducing the risk of heat-affected zones that could compromise weld integrity. Real-time data monitoring enables dynamic adjustments based on current conditions, ensuring the most efficient cooling performance. Implementing such advanced thermal management not only assures precision welding but also elevates the overall reliability of the laser welder machine.

Energy Efficiency & Reduced Operational Costs

Smart cooling systems in fiber laser welding can dramatically cut energy usage, thereby reducing operational costs. Studies indicate that these systems can cut energy consumption by up to 30%, which substantially contributes to cost savings over time. This translates to a promising return on investment through lowered utility bills. Additionally, these systems minimize wear and tear on equipment, potentially extending the lifespan of laser welding machinery. Investing in energy-efficient cooling technologies not only reduces expenses but also enhances the sustainability of laser welding operations, making them a smart choice for any business looking to optimize its fiber laser cutting machine processes.

Key Innovations in Modern Fiber Laser Welding Technology

Integration with Automation and AI-Driven Systems

The synergy of automation and AI-driven systems with fiber laser welding technology is a game-changer for industries. By integrating AI, we enhance operational efficiency through process automation, which significantly reduces human error and increases precision. These automated systems allow for real-time adjustments, enabling laser welding machines to adapt swiftly to varying materials and thicknesses. The advanced AI algorithms further facilitate predictive maintenance, ensuring that machines operate at optimal levels by anticipating and mitigating potential issues before they cause downtime. Statistics have shown that incorporating automation in manufacturing can boost productivity by up to 25%, making this integration incredibly valuable for businesses aiming to streamline operations and elevate output quality.

High-Speed Performance for Industrial Demands

Modern fiber laser welding machines are engineered to meet the high-speed demands of industrial production. They achieve rapid welding speeds while maintaining uncompromised quality, a necessity in high-demand sectors such as automotive and aerospace. Innovations in fiber laser technology have resulted in operational speeds that surpass traditional welding methods by up to 50%, signifying a notable leap in manufacturing capabilities. This increased performance is aligned with industry trends towards faster production cycles, ensuring that enterprises remain competitive in a fast-paced market. As speed and efficiency are crucial for industrial application, fiber laser welding technology stands as a vital component in today's manufacturing strategies, addressing the growing need for swift yet precise production processes.

Voiern Laser Solutions: Smart Fiber Laser Cutting Machines

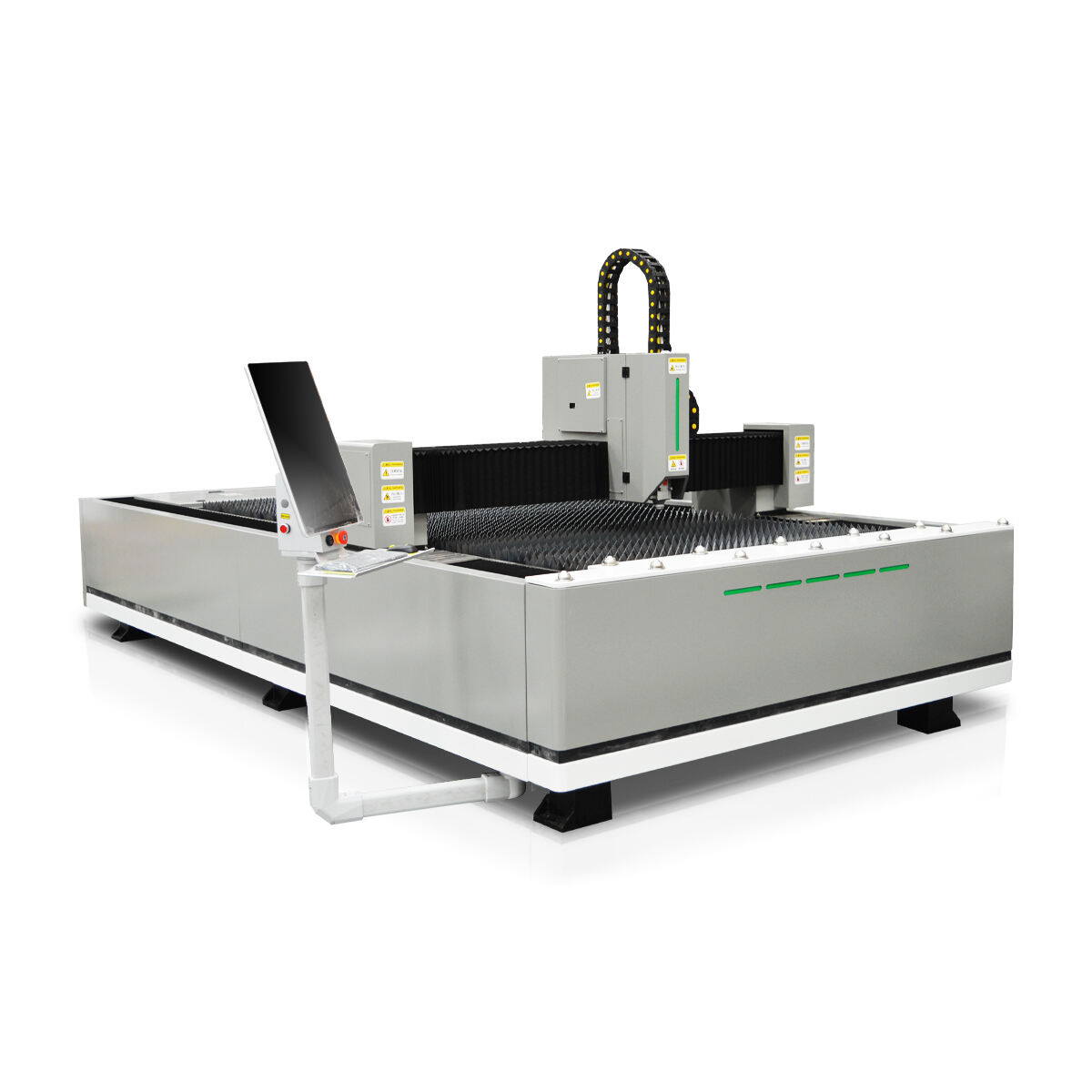

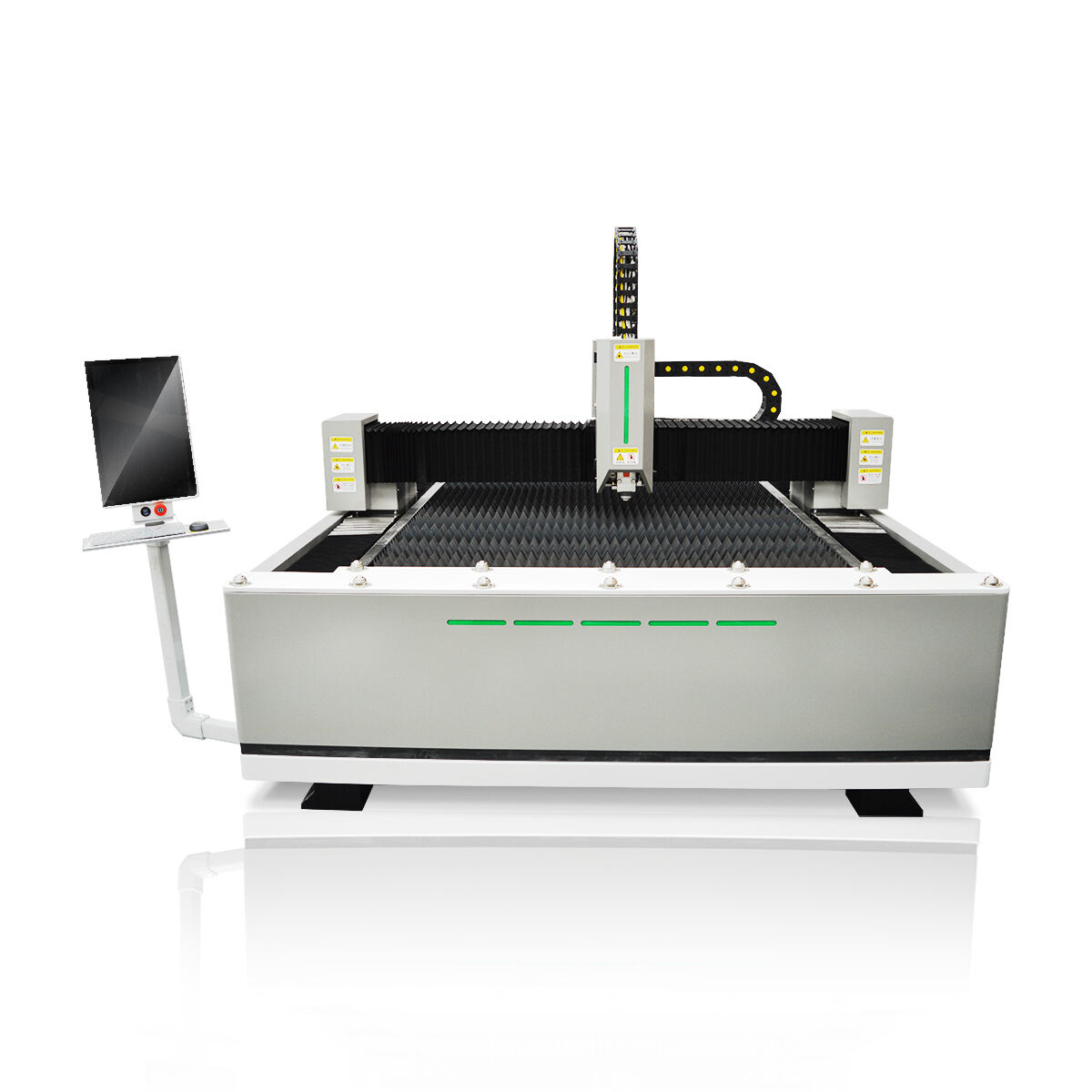

Fiber Laser Cutting Machine 1530: Ultra-Low Cost & High Speed

The Voiern Fiber Laser Cutting Machine 1530 sets a new standard by merging cutting-edge technology with cost-effective operation. This machine is known for its remarkable high-speed cutting capabilities while maintaining precise results. Industry experts highlight that machines like the 1530 can notably decrease operational costs, with some reports suggesting a potential reduction of up to 40% compared to traditional cutting methods. Feedback from users emphasizes their satisfaction with the machine's performance-price balance, making it a preferred choice for small to mid-sized businesses aiming for both efficiency and affordability.

Fiber Laser Cutting Machine 1530: Precision Cutting for Complex Designs

This machine excels in precision, allowing intricate designs and complex shapes to be flawlessly executed. With nanosecond-level pulse control, the Fiber Laser Cutting Machine 1530 provides unmatched accuracy in threading, filleting, and sharp corners. Voiern's technology boasts a cutting tolerance as low as ±0.1mm, which is ideal for high-quality applications. Case studies consistently show the machine's efficacy in sectors demanding precision, such as jewelry and aerospace manufacturing, where every detail is critical.

Future Trends in Laser Welding and Cutting Systems

Sustainable Laser Technology: Eco-Friendly Manufacturing

The shift towards sustainable practices in manufacturing is driving the development of eco-friendly laser technologies. Innovations such as recycling waste material generated during the cutting and welding processes are being adopted to minimize environmental impact. By integrating these practices, companies not only contribute to ecological preservation but also increase brand loyalty among environmentally conscious consumers. Research further suggests that sustainable manufacturing practices can enhance profitability while addressing ecological concerns. Such advancements are propelling the industry towards a greener, more responsible future.

Multi-Functional Systems for Welding and Cutting Integration

Modern manufacturing demands efficiency and versatility, fostering the development of systems designed to perform both welding and cutting tasks. By utilizing multifunctional machines, manufacturers can reduce the need for multiple types of equipment, optimizing floor space in workshops and streamlining operations. Integrated systems significantly lower the initial investment and maintenance costs while maximizing throughput. Statistics show that multifunctional systems can boost productivity by up to 30% by facilitating smoother processes. These systems embody the future of manufacturing, offering a comprehensive solution to meet diverse needs efficiently.

For further exploration of products encapsulating these advanced technologies, consider checking out our range of laser welding and cutting systems. From fiber laser cutting machines to portable welding solutions, these technologies are designed to enhance performance, precision, and sustainability across various applications.