How to Select the Right Fiber Laser Cutting Machine for Your Business Needs

Key Factors in Choosing a Fiber Laser Cutting Machine

Material Compatibility and Thickness Requirements

When selecting a fiber laser cutting machine, it's crucial to identify the types of materials you intend to cut, such as metals, plastics, or composites, and consider their corresponding thicknesses. For instance, the cutting thresholds differ significantly between stainless steel, aluminum, and carbon steel, each of which requires different power settings for effective cutting. This understanding aids in assessing the machine’s versatility. Industry standards suggest that optimal thickness cutting varies across machines, so adhering to manufacturer specifications is essential to ensure accurate cuts and extend the lifespan of the cutting tool. This step is particularly important for users needing consistency in complex metalwork.

Laser Power and Cutting Speed Considerations

Exploring the correlation between laser power and cutting speed is fundamental when choosing a fiber laser cutting machine. Generally, higher wattage translates to faster cutting speeds, meaning machines with enhanced power capabilities can significantly boost productivity without sacrificing precision. This balance between power and speed is crucial; too much power might burn through delicate materials, while insufficient power can lead to inaccurate cuts. Market research indicates that various industry sectors prefer specific power ratings, which can guide users in selecting the most suitable machine. Higher power machines are typically favored by industries requiring high throughput and efficient operations.

Precision Requirements for Your Applications

The need for precision varies significantly across different industries such as automotive, aerospace, and jewelry design, each requiring specific tolerances. The level of precision is influenced by the construction of the machine, the quality of its optics, and its software capabilities. High-precision fiber laser cutting machines are invaluable for minimizing waste and reducing rework, thus supporting high-quality production. Studies have demonstrated that precision in cutting not only improves finished product quality but also enhances overall production efficiency, leading to fewer errors and rejections. This makes it crucial for manufacturers to invest in equipment that meets their specific precision demands.

Technical Specifications to Evaluate

Machine Dimensions vs Workshop Space

When investing in a fiber laser cutting machine, it's crucial to assess the machine dimensions relative to your workshop space. Ensuring the machine's footprint fits well within your available area is important for maintaining operator mobility and adhering to safety standards. Additionally, planning for adequate ventilation and material storage is necessary when positioning larger machines to ensure a safe operating environment. Industry guidelines suggest maintaining a minimum clearance around laser-cutting machines to uphold safety protocols and allow for efficient workflow.

Control Systems and Software Integration

The integration of user-friendly control systems is essential for efficient operation of fiber laser cutting machines. These systems enable operators to program cuts accurately and streamline production processes. It’s important to ensure compatibility with existing CAD/CAM software, facilitating seamless workflow integration. Studies have demonstrated the impact of efficient software integration in reducing setup times and boosting production rates. This compatibility not only enhances productivity but also minimizes programming errors, ensuring high precision in cutting tasks.

Maintenance Needs and Component Quality

Understanding the maintenance requirements of fiber laser cutting machines is vital for prolonging their lifespan and ensuring optimal performance. Routine maintenance, including servicing and the replacement of consumables, needs to be factored into decision-making. The quality of components, such as optics and lasers, directly affects both machine performance and the frequency of maintenance tasks. Experts recommend investing in high-quality components to minimize wear and tear and reduce the overall cost of maintenance. This approach not only lengthens the machine's operational life but also maximizes uptime, which is essential for productivity.

Evaluating Fiber Laser Cutting Machine Manufacturers

Certifications and Quality Standards

Certifications play a crucial role in evaluating fiber laser cutting machine manufacturers. These certifications, such as ISO 9001, signify that a manufacturer adheres to international quality standards, ensuring that their products meet high levels of reliability and performance. Choosing a supplier possessing these certifications can enhance trustworthiness and dependability for customers who rely on consistent machinery quality. Industry data reflects that approximately 75% of laser cutting machine manufacturers possess some form of certification, underscoring their importance in establishing supplier trust and industry norms.

After-Sales Support and Service Networks

An essential aspect of selecting a fiber laser cutting machine supplier is the robustness of its after-sales support and service networks. This factor is crucial because it guarantees quick resolution of any issues, thereby minimizing downtime and maintaining operational efficiency. A well-developed service network ensures that service response times are competitive, promoting unhindered production schedules. Statistics indicate that manufacturers with comprehensive service networks tend to resolve technical issues 35% faster than those without, providing a significant boost to operational continuity and efficiency.

Supplier Reliability and Customization Options

When evaluating fiber laser cutting machine suppliers, considering reliability based on customer reviews and long-term partnerships can reveal insights into their dependability. Case studies often highlight how reliable suppliers contribute to enhanced production outputs over prolonged collaborations. Another key factor is the range of customization options available. These enable companies to tailor machinery to specific industry needs, providing unique solutions. Survey data illustrates that there is a growing demand for customizable features, with 60% of manufacturers seeking equipment that can be specifically configured to their operational requirements. This trend underscores the importance of supplier flexibility in the evolving landscape of industrial manufacturing.

Cost Analysis and Energy Efficiency

Initial Investment vs Operational Costs

When purchasing a fiber laser cutting machine, it's crucial to weigh the initial investment against the ongoing operational costs. The upfront price of a machine can vary widely based on features, power output, and manufacturing origin, but the true cost becomes evident only when considering operational expenses. Hidden costs like maintenance, power consumption, and replacement parts play a significant role in long-term budgeting. Conducting a thorough cost-benefit analysis before making a purchase decision is essential. For context, it's worth noting that industry statistics indicate that operational costs can account for 20-30% of the total cost over the product’s lifetime, which can drastically influence the return on investment (ROI) expectations.

Power Consumption and Gas Requirements

A fiber laser cutting machine's power consumption significantly impacts its operational expenses. On average, these machines convert 70% of electricity into laser power, making them more energy-efficient than older CO2 lasers. However, they still require substantial electricity input for optimal performance. Additionally, gases like oxygen or nitrogen are often necessary for the cutting process to improve cutting speed and quality, contributing further to operational costs. By addressing these factors, manufacturers can better estimate their long-term energy costs. For instance, manufacturer data reveals that energy costs can range from $3 to $5 per hour depending on the machine model and usage intensity.

ROI Calculation for Different Models

To make an informed purchase, it's beneficial to calculate the ROI based on the initial cost, operational savings, and efficiency gains of different fiber laser cutting machine models. The efficiency of these machines often results in time and cost savings, enhancing profitability. Generally, a good machine should offer an ROI within 12-18 months, contingent on the cutting volume and operating conditions. Real-world case studies show, for example, that companies switching to fiber laser from traditional cutting methods often experience a 15% boost in production efficiency, which translates to faster ROI. These potential efficiency gains underscore the importance of selecting the right model tailored to specific industry needs.

Featured Fiber Laser Cutting Machine Models

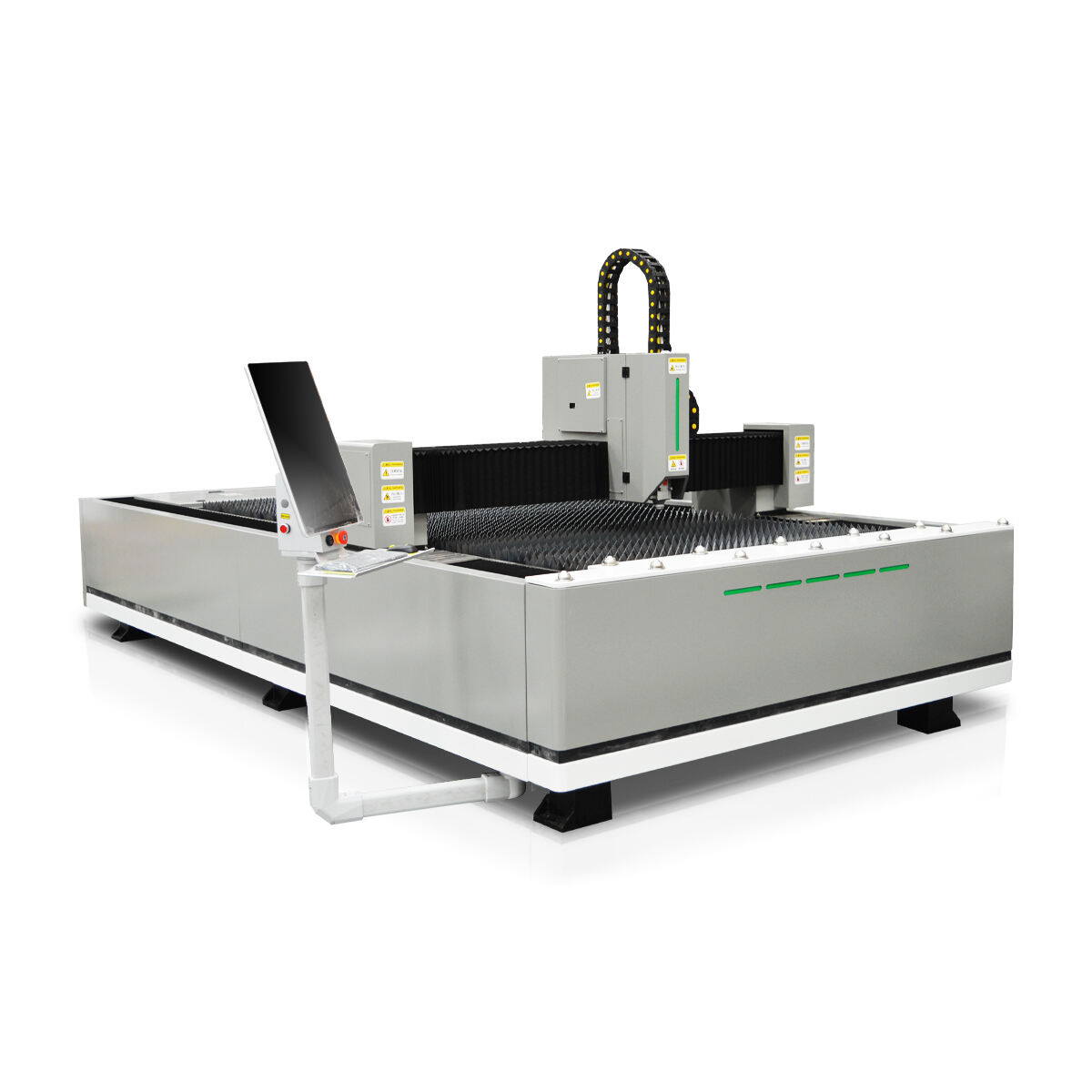

WR 1530 Fiber Laser Cutting Machine: High-Speed Precision

The WR 1530 model is a standout option for businesses seeking high-speed precision cutting. Known for its exceptional performance in high-demand environments, this machine combines advanced technology with reliability. The WR 1530 boasts cutting speeds that reach over ten meters per minute, making it an ideal choice for industries that require rapid processing of materials like stainless steel, titanium, and copper. Importantly, this model features imported high precision guide rails and servo motors, which enhances both its speed and accuracy in cutting.

Specifications for the WR 1530 are impressive, setting a benchmark for precision and capability. The machine includes an imported original fiber laser with a lifespan exceeding 100,000 hours, ensuring prolonged periods of efficient operation. A user-friendly interface allows for the design and instant cutting of various graphics or words, adding flexibility to its list of features. User testimonials consistently highlight the model's reliability and robust performance, cementing its reputation in the field.

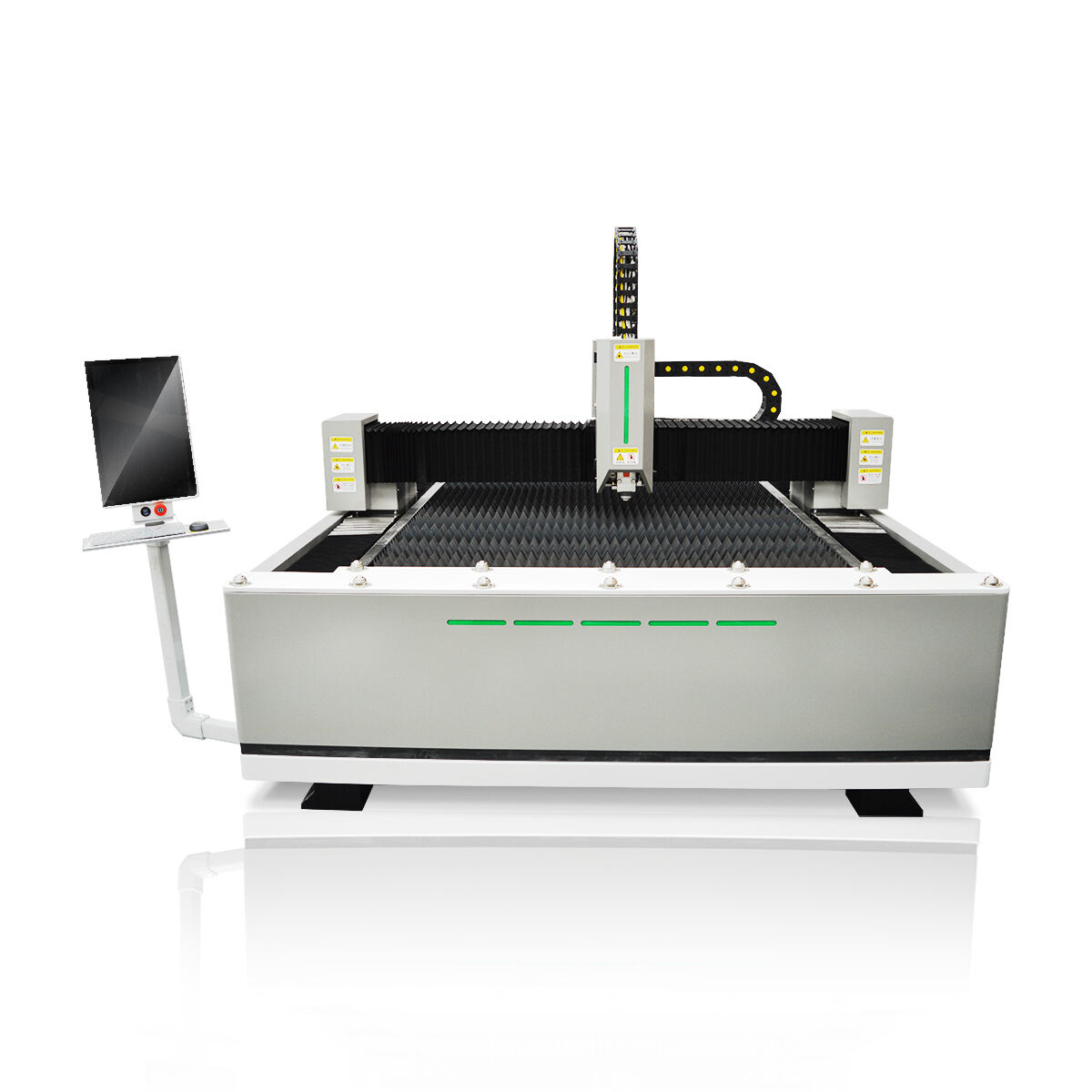

Advanced 1530 Model: Ultra-Low Energy Consumption

The Advanced 1530 model stands out with its focus on energy efficiency and environmental sustainability. By utilizing cutting-edge technology, this model effectively reduces energy consumption, making it an excellent investment for companies looking to minimize their carbon footprint while maintaining productivity. This feature alone allows for significant savings compared to traditional models, which can contribute to lower overall operational costs.

Comparing operational expenses, the Advanced 1530 shows remarkable improvements over other models. Its design ensures that energy usage remains at an optimum low, facilitating cost savings without sacrificing performance. Large enterprises have reported impressive reductions in their overall consumption, supporting the model’s claim to efficiency. These case studies highlight the Advanced 1530 as not only a cost-saving solution but also an environmentally responsible choice for modern industries.