Maintenance Practices for Extending the Lifespan of Fiber Laser Cutting Machines

Essential Maintenance Routines for Fiber Laser Systems

Daily Cleaning Protocols for Optimal Performance

Daily cleaning of fiber laser cutting machines is crucial for maintaining their optimal performance. Establishing a routine cleaning schedule ensures that operators consistently clean lenses and mirrors, removing any dust and debris that might obstruct the machine's efficiency. Utilizing non-abrasive, specialized cleaning solutions is vital to avoid damaging sensitive surfaces such as the optics within the machine. Documentation of cleaning activities helps track improvement in performance and detect any issues that arise from a lack of maintenance. Proper maintenance not only prolongs the lifespan of fiber laser cutting machines but also enhances cutting accuracy and efficiency, ultimately benefiting the bottom line. Fiber laser cutting systems demand meticulous care; hence embracing daily cleaning routines is a necessity for operators seeking to maintain peak operational capabilities.

Weekly Gas System Checks and Calibration

Weekly checks and calibration of the gas system are imperative in sustaining optimal fiber laser performance. Checking gas purity levels is essential because impurities can significantly affect cutting quality. Impure gases can lead to aberrations in laser focus, causing inefficiencies in cutting operations. Calibrating pressure and flow rates according to manufacturer specifications allows for the early detection of discrepancies that could impact machine functionality. Maintaining a checklist of past gas system readings and adjustments provides insights into trends, indicating potential issues. This approach aids operators in sustaining the cutting machine's high performance over time, ensuring consistent and quality outputs. Regular gas system evaluations ensure that fiber laser cutting machines operate smoothly and efficiently, minimizing unexpected downtime due to gas-related issues.

Monthly Cooling System Inspections

Monthly inspections of the cooling system are critical to preventing overheating during fiber laser operations. Inspecting coolant levels and topping them up as necessary safeguards against potential heat damage to the machine, which can occur during extended use. Ensuring that the cooling system is free of leaks and that all pumps function correctly minimizes the risk of operational interruptions and mechanical failures. Additionally, evaluating the efficiency of the coolant provides opportunities to replace it as per manufacturer recommendations, ensuring the system operates at peak efficiency. These inspections contribute significantly to the longevity of the fiber laser cutting machine by sustaining optimal thermal conditions. Routine checks on the cooling system are fundamental in maintaining dependable and efficient operations, aligning with the goal of achieving optimal business productivity through well-maintained equipment.

Critical Components Requiring Regular Attention

Laser Head and Optics Maintenance Best Practices

The laser head and optics are pivotal components in any fiber laser cutting machine, demanding regular scrutiny to prevent costly repairs and downtime. Regular inspection for signs of wear or damage is crucial because even minor issues can escalate, impacting machine performance. To maximize efficiency, applying proper cleaning techniques for optics is vital; this minimizes scratches and prolongs the lifespan of these costly elements. Additionally, consistently monitoring the output power helps ensure that the system operates at peak performance, allowing adjustments as necessary to maintain optimal functionality.

Guide Rail Lubrication and Drive System Care

Maintaining smooth operation of the guide rails and drive system in fiber laser machines requires a defined lubrication schedule based on operating hours. Lubricating regularly prevents friction and wear that could compromise machine precision. Selecting the right lubricant as recommended by the manufacturer is essential; this ensures optimum performance and longevity of the components. Routine inspections should include checks for any signs of damage or misalignment in the guide rails and drive system, enabling timely interventions to prevent major issues.

Monitoring Gas Purity and Flow Rates

To safeguard performance and maintain cutting quality, ongoing monitoring of gas purity and flow rates is indispensable. Investing in gas analyzers allows for precise assessments of purity levels, preventing contamination that could affect machine efficiency. Documenting flow rate checks and analyzing them against operational standards aid in identifying inconsistencies before they cause problems. Forming partnerships with reliable gas suppliers is another beneficial strategy to mitigate risks of contamination, ensuring a steady supply of clean gas at all times.

Featured Fiber Laser Cutting Machines from Trusted Manufacturers

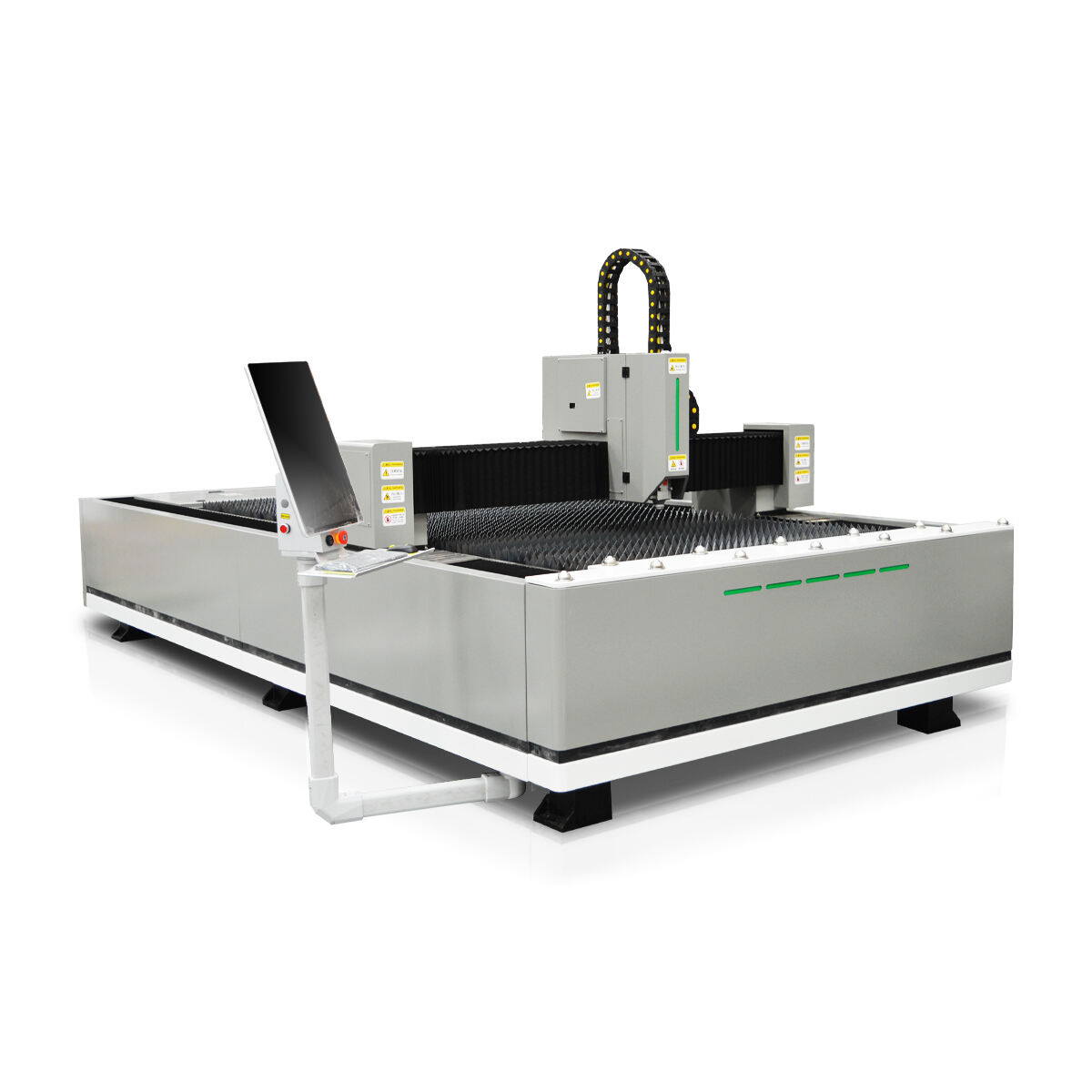

WR 1530 Fiber Laser Cutting Machine: High-Speed Precision

The WR 1530 Fiber Laser Cutting Machine stands out due to its advanced technology, specifically engineered for high-speed precision in metal cutting. This machine boasts remarkable cutting quality, ensuring clean and accurate cuts that are highly valued across various industries. Testimonials from satisfied clients reveal significant improvements in production efficiency and product quality after integrating this machine. Furthermore, its energy-efficient design plays a pivotal role in reducing operational costs, making it a smart investment for businesses aiming for sustainability and cost-effectiveness.

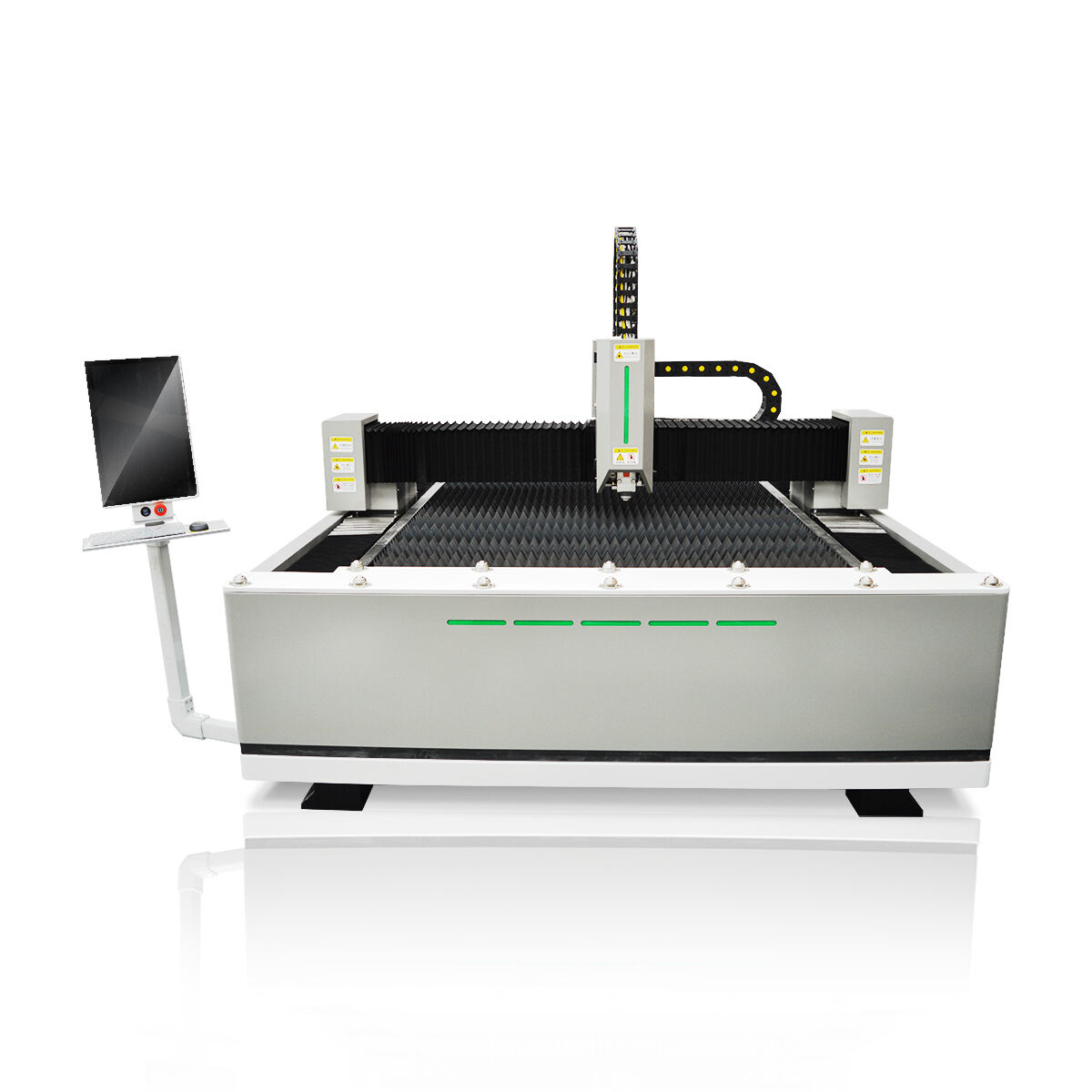

High-Performance 1530 Model: Energy-Efficient Design

The High-Performance 1530 Model takes innovation a step further, integrating energy-efficient design principles without compromising on performance. Its cutting-edge features ensure optimal performance in energy usage, making it a competitive choice against similar models. The 1530 model's advantages are evident when compared to other machines, giving it an edge in versatility and operational excellence. Feedback from industry experts highlights its reliability and adaptability across different applications, reinforcing its reputation as a top-tier solution in fiber laser cutting.

Enhancing Longevity Through Best Practices

Importance of Genuine Replacement Parts

Using genuine replacement parts in fiber laser cutting machines is crucial for maintaining their longevity and efficiency. Non-genuine parts pose significant risks, including system failures and potential safety hazards, as they may not meet the specific technical and material standards required by original manufacturers. Genuine parts, on the other hand, ensure compatibility and reliability over time, fitting seamlessly into the existing system and functioning as intended by the designers. Studies have shown that machines using authentic parts had a 30% lower failure rate and demonstrated more consistent performance over prolonged periods. These statistics emphasize the tangible benefits of investing in original components, ensuring your fiber laser cutting machine operates smoothly and efficiently [*Source: Fiber Laser Cutting Machine: Accessories Selection Guide (2025)*].

Software Updates for Improved Cutting Accuracy

Regular software updates are vital for enhancing the functionality of fiber laser cutting machines. These updates ensure that the machine operates with the latest features and improvements, consequently enhancing cutting accuracy. Best practices for managing updates include scheduling them during planned downtime to minimize disruption to production schedules. Recent software updates have introduced significant features, such as advanced nesting algorithms that optimize material usage and enhancements to cutting speed settings, which collectively improve operational efficiency. As machines evolve, staying updated helps maintain competitive edge and operational proficiency.

Operator Training for Consistent Maintenance

Operator training plays a crucial role in the consistent maintenance and optimal performance of fiber laser cutting machines. Comprehensive training programs equip operators with the essential skills needed for precise machine handling and routine maintenance tasks. It's important to encourage ongoing training sessions that reflect technological advancements in fiber laser systems. Research has shown that facilities with well-trained operators experience up to 40% less downtime and reduced maintenance costs. This statistic underscores the value of investing in continuous skill enhancement to maximize the operational lifespan and reliability of fiber laser cutting machines.

In conclusion, the integration of best practices such as using genuine parts, staying current with software updates, and ensuring comprehensive operator training significantly enhances the longevity and efficiency of fiber laser cutting machines. These strategies not only maintain the machine's peak performance but also provide a competitive advantage in various industrial applications.