What Materials Can Be Processed with a CO₂ Laser Engraving Machine?

Overview of CO₂ Laser Engraving Material Compatibility

How CO₂ Lasers Interact with Different Materials

CO₂ lasers, operating primarily at a wavelength of 10.6 micrometers, excel in interacting with organic materials through a process of absorption. This specific wavelength ensures effective engraving and cutting techniques, particularly for materials such as wood, acrylic, and leather. These materials absorb CO₂ laser energy with high efficiency, resulting in precise, clean cuts and intricately detailed engravings. However, substrates like certain metals and glass do not inherently absorb CO₂ wavelengths, necessitating additional preparation, such as applying coatings or using pre-treatment. An important advantage of CO₂ laser interaction is the minimal heat-affected zones that it produces, ensuring that the integrity of the material in surrounding areas remains intact, making it an ideal choice for craftsmanship requiring high precision.

Benefits of Using CO₂ Lasers for Engraving

CO₂ lasers provide numerous benefits for engraving, offering precision and versatility across multiple applications. From intricate patterns on wood to detailed acrylic engravings, these lasers are adept at reducing production time significantly compared to traditional methods, boosting productivity and operational efficiency in workshops. Additionally, CO₂ laser engravers are cost-effective; they incur lower maintenance costs and boast long operational lifespans, driving down overall operating expenses. The lasers also ensure a high-quality finish, producing smooth edges and often eliminating the need for extensive post-processing. This efficiency and quality make CO₂ lasers an invaluable tool in professional-grade output scenarios where appearance and detail are critical.

Common Materials Processed with CO₂ Laser Engraving Machines

Wood and Plywood: Precision for Crafts and Signage

Wood is inherently compatible with CO₂ laser engraving, offering precise and intricate designs owing to its organic nature. The energy from the laser is absorbed efficiently, allowing for detailed customization in applications like custom signage, decorative crafts, and furniture design. Various wood types, from hardwoods to softwoods, respond differently to laser settings, necessitating tailored configurations for achieving optimal results. The ability to personalize wooden items through intricate engraving makes CO₂ lasers a crucial tool for artists and craftsmen CO₂ Laser Cutting and Engraving Machine.

Acrylic and Plastics: Smooth Edges & Detailed Designs

CO₂ lasers excel at engraving and cutting acrylic materials, ensuring clean and smooth edges that are vital for applications like signage and displays. Acrylic's excellent laser absorption properties make it ideal for creating detailed patterns, a preferred choice in the promotional products industry. Clear and colored acrylic sheets can yield different aesthetic results, enhancing creativity in design approaches. The versatility of these lasers allows them to tackle multiple types of plastics, ensuring precise and attractive outputs.

Leather and Fabric: Ideal for Textile Customization

CO₂ lasers are particularly efficient in engraving leather, producing crisp etchings that enhance branding on products such as wallets and purses. These lasers accommodate the textile industry by enabling high-precision customization for fashion and upholstery. To prevent damage to delicate fabrics while achieving deeper engravings, adjustments to speed and power settings are essential. This flexibility provides brands with the ability to create unique patterns and logos that stand out in the marketplace. For additional details on processing fabrics and leather, explore CO₂ Laser Engraving Machine.

Glass and Stone: Frosted Effects and Artistic Engraving

While CO₂ lasers face challenges with glass, skilled techniques can produce attractive frosted effects on glassware and decorative items. Engraving stone with CO₂ lasers results in permanent designs, making it suitable for awards, memorials, and decorative pieces. Mastering the specific settings for power and focus is crucial to avoid fractures and achieve the desired depth in engraving. This capability allows for the creation of both functional and artistic objects with unique and lasting marks.

Paper/Cardboard: Intricate Cutting for Packaging

CO₂ lasers efficiently cut and engrave paper and cardboard, making them ideal for applications like packaging, invitations, and creative arts. The ability to engrave fine details enhances visual appeal, while custom cuts lead to innovative packaging solutions. Processing various paper types, from cardstock to heavier cardboard, broadens creative applications across arts and industries. This versatility makes CO₂ laser machines a staple in industries that rely on precision and aesthetic value. Learn more about processing cardboard with laser technology through our CO₂ Laser Engraver.

Material Limitations of CO₂ Laser Engravers

Metals: Why CO₂ Lasers Struggle Without Coatings

CO₂ lasers generally struggle to engrave uncoated metals due to their low absorption rates. The typical wavelength of CO₂ lasers is not well-absorbed by metals, which often necessitates the use of coatings or pre-treatments to enhance engraving capabilities. For instance, materials such as stainless steel and aluminum require surface preparation to interact effectively with the CO₂ laser. Although adjusting laser power and speed can sometimes yield satisfactory results, these adjustments are far less efficient compared to using fiber or YAG lasers, which are specifically designed for metal engraving. Consequently, CO₂ lasers are better suited for non-metal applications unless special measures are taken.

PVC and Hazardous Fumes: Safety Considerations

When using CO₂ lasers on PVC materials, operators must be aware of the hazardous fumes generated during the process. Engraving PVC produces toxic fumes, such as hydrochloric acid, which poses significant health risks, particularly in enclosed spaces. Moreover, these fumes can corrode internal parts of the laser machine, making it essential to avoid using CO₂ lasers for processing PVC. To mitigate these dangers, safety protocols must be established, including adequate ventilation systems to manage the emission of hazardous gases effectively. Ensuring a safe working environment by following these precautions is critical.

Top CO₂ Laser Machines for Material Processing

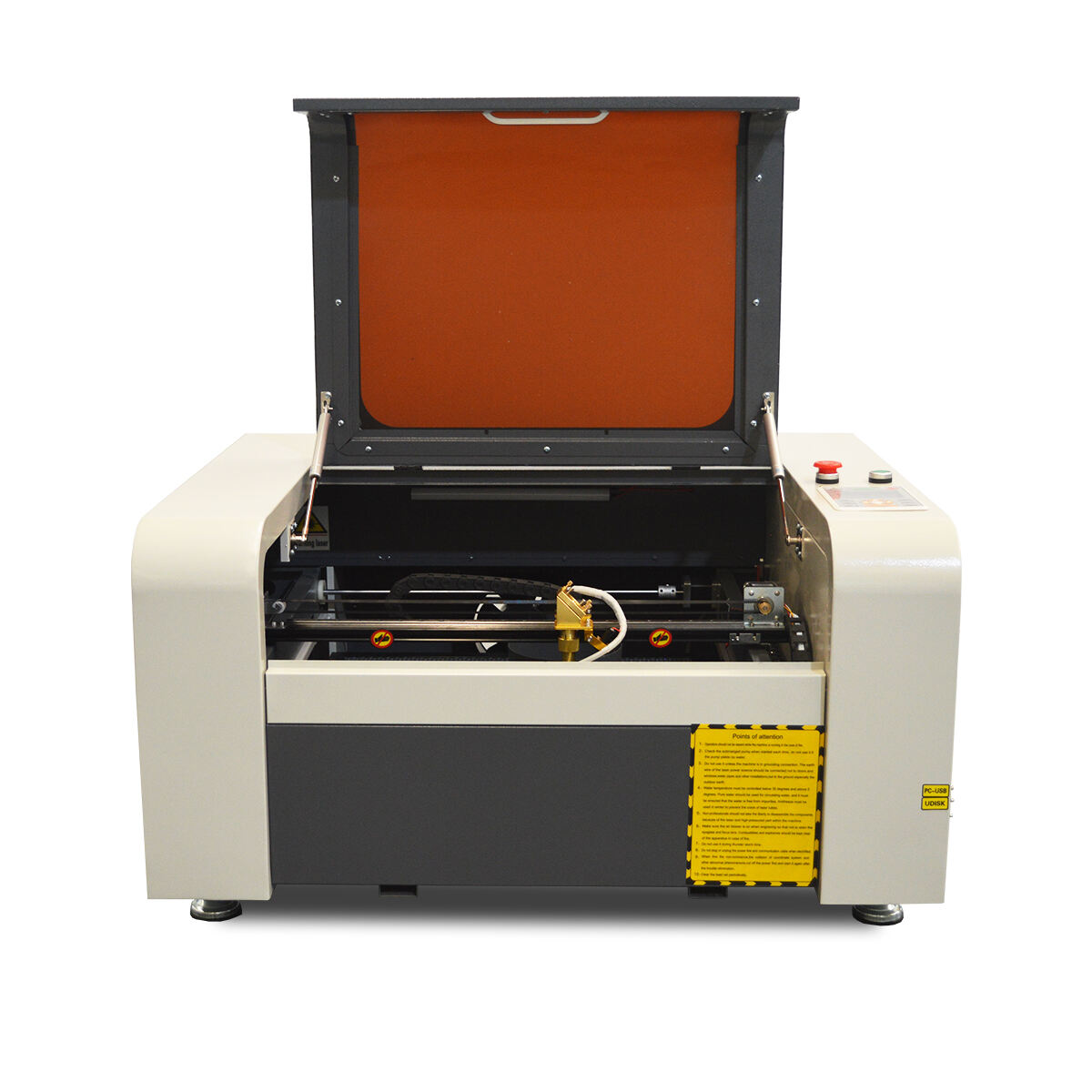

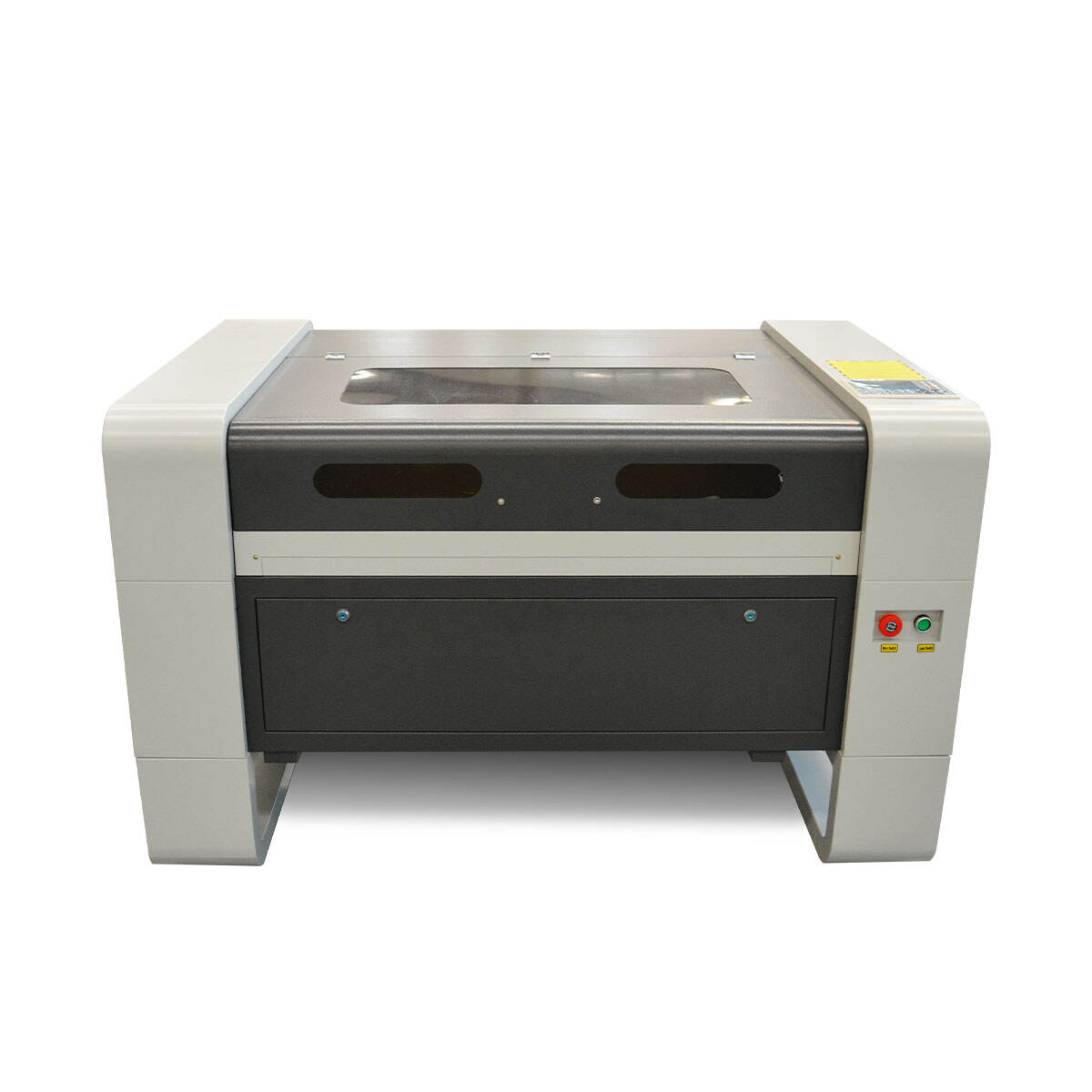

Laser Engraving and Cutting Machine 3020: Compact Precision

The Laser Engraving and Cutting Machine 3020 stands out for its compact precision, making it ideal for small-scale operations. This machine is perfect for personal projects or small businesses that require intricate designs, a popular choice among hobbyists. Its competitive pricing, relative to its features, makes it especially appealing for entry-level users seeking to venture into the world of laser engraving. The machine is designed to offer high precision in a small footprint without compromising on quality, allowing for detailed and accurate work on various materials.

Laser Engraving and Cutting Machine 4040: Enhanced Workspace

The Laser Engraving and Cutting Machine 4040 is designed to offer an enhanced workspace, allowing it to accommodate larger projects while maintaining precision. This makes it suitable for small to medium businesses that require versatility in material processing, enabling diverse applications. The increased workspace minimizes the need for multiple setups, thereby enhancing efficiency in various engraving tasks. Its flexible design supports numerous applications, making it a versatile choice for varied material processing.

Laser Engraving and Cutting Machine 4060: High-Speed Performance

The Laser Engraving and Cutting Machine 4060 emphasizes high-speed performance, making it ideal for commercial applications demanding rapid output. Designed for professional settings, it can handle various materials while consistently ensuring high-quality results. The adjustable settings and enhanced optics allow users to optimize performance based on specific material requirements, enhancing efficiency and precision. This makes the 4060 model a robust choice for businesses requiring quick turnaround without sacrificing quality.

Laser Engraving and Cutting Machine 7050: Industrial-Grade Power

The Laser Engraving and Cutting Machine 7050 is equipped with industrial-grade power, designed for heavy-duty, continuous operation that suits the demands of large companies. It can process a wide range of materials, including denser substrates, offering significant versatility in production tasks. Its advanced cooling systems help reduce wear from extended use, thereby prolonging service life and maintaining consistent performance even under tough conditions. This makes the 7050 model an optimal choice for industries with intensive material processing needs.

Laser Engraving and Cutting Machine 9060: Large-Format Versatility

The Laser Engraving and Cutting Machine 9060 offers large-format processing capabilities, making it suitable for businesses involved in signage, furniture, and architectural designs. Providing maximum versatility, this machine can process various materials with intricate cuts and designs, making it ideal for large surface projects. Its robust construction and powerful performance ensure consistent, high-quality results even for the most demanding applications, making it a valuable addition to any large-scale production line.

Optimizing CO₂ Laser Settings for Material Types

Adjusting Power and Speed for Wood vs. Acrylic

Achieving optimal engraving results on different materials requires adjusting the power and speed settings of your CO₂ laser machine. When working with wood, a higher speed with medium power settings is ideal, as wood responds well to these adjustments, producing precise and clean engravings. Conversely, acrylic demands lower speeds to effectively cut through without melting edges, thereby maintaining the quality of the finish. Understanding the material composition, including its density and thickness, is crucial in determining these settings. By expertly adjusting your laser power settings, you can ensure that each material is processed efficiently, enhancing the overall quality of your engraving projects.

Cooling Systems and Ventilation for Safe Processing

Efficient cooling systems are essential when using a CO₂ laser engraving machine for extended sessions, as they help maintain suitable operating temperatures and prevent overheating. Proper ventilation also plays a crucial role in removing smoke and fumes generated during laser processing, thereby ensuring a safe working environment. By prioritizing the maintenance of these systems, not only is machine longevity prolonged, but performance efficacy is also significantly enhanced. Through regular inspection and adjustment of cooling and ventilation mechanisms, users can minimize wear and ensure optimal engraving conditions, ultimately leading to more consistent and high-quality outputs.