When you’re looking for a heavy-duty laser cutter and engraver to use on metal, there’s more to take into consideration. At Voiern, we understand that when it comes to metalworking, what you need is precision and power and the right tools can make all the difference. If you’re cutting more traditional materials like steel, aluminum and brass for largely professional-level purposes, a heavy-duty laser cutter could be just what you need to create clean cuts or engravings with great detail. Whether you are working in a shop with limited space, tinkering in your garage or managing an industrial workplace, finding the best laser cutter can make a world of difference on all kinds of projects. This post will show you some useful tips and how to use high power laser cutter for metal processing perfectly.

Tips for Success

When it comes to using a robust laser cutter, you need to make sure you have the best set-up. A tidy workspace lets you concentrate and protects your supplies. Make certain to also read the user manual that came with your machine. It contains vital information about safety and operation. Above all, safety comes first. Always use safety gear, such as goggles and gloves, while working. That will help protect you from sparks and bright flashes of light generated by the laser. Then choose the correct ones for the metal you are cutting. Various metals need varying power levels and speeds. It will require more power for instance to cut through thick steel as opposed to thin aluminum. Testing your settings on scrap metal can help you save materials and time. And don’t forget to service your equipment. Be sure that the lens is clean and does not show any signs of damage. A well-oiled machine runs faster and longer. Finally, feel free to ask for help if you’re not sure about something. Whether it’s someone at work or an online forum, hearing suggestions from others can help enhance your skills and increase your knowledge.

Getting The Most Out of Heavy Duty Laser Engravers In Metal Fabrication

In order to maximize your heavy-duty laser engraving machine, it's important to have a plan. To begin, you can sketch out your designs and think about how you’ll arrange pieces on the metal sheet before starting work. This helps in minimizing waste. Designs Use with the software you already like and engrave whatever you want into virtually any material. Some programs will let you preview what the finished product will look like. Just make sure your machine is set up right Doing it includes finding the correct calibration. Calibration involves adjusting the laser so that it cuts precisely where you would like. When it’s not calibrated, you can make the wrong cuts and waste materials. Timing is also important. Working with efficiency is about just knowing how long each cut took, and being organized about your tasks. You can also create a schedule to engage in various parts of a project for seamless operations. And watch the machine as it runs. That way you can catch any problems early and address them before they become more significant issues. Finally, we learn from every project and get better. After a job is finished, consider what went right and what could be improved next time. That continuous improvement mentality can result in increased efficiency and improved outcomes over time.

Why a Heavy Duty Laser Cutter is Necessary for Any Professional Metal Shop

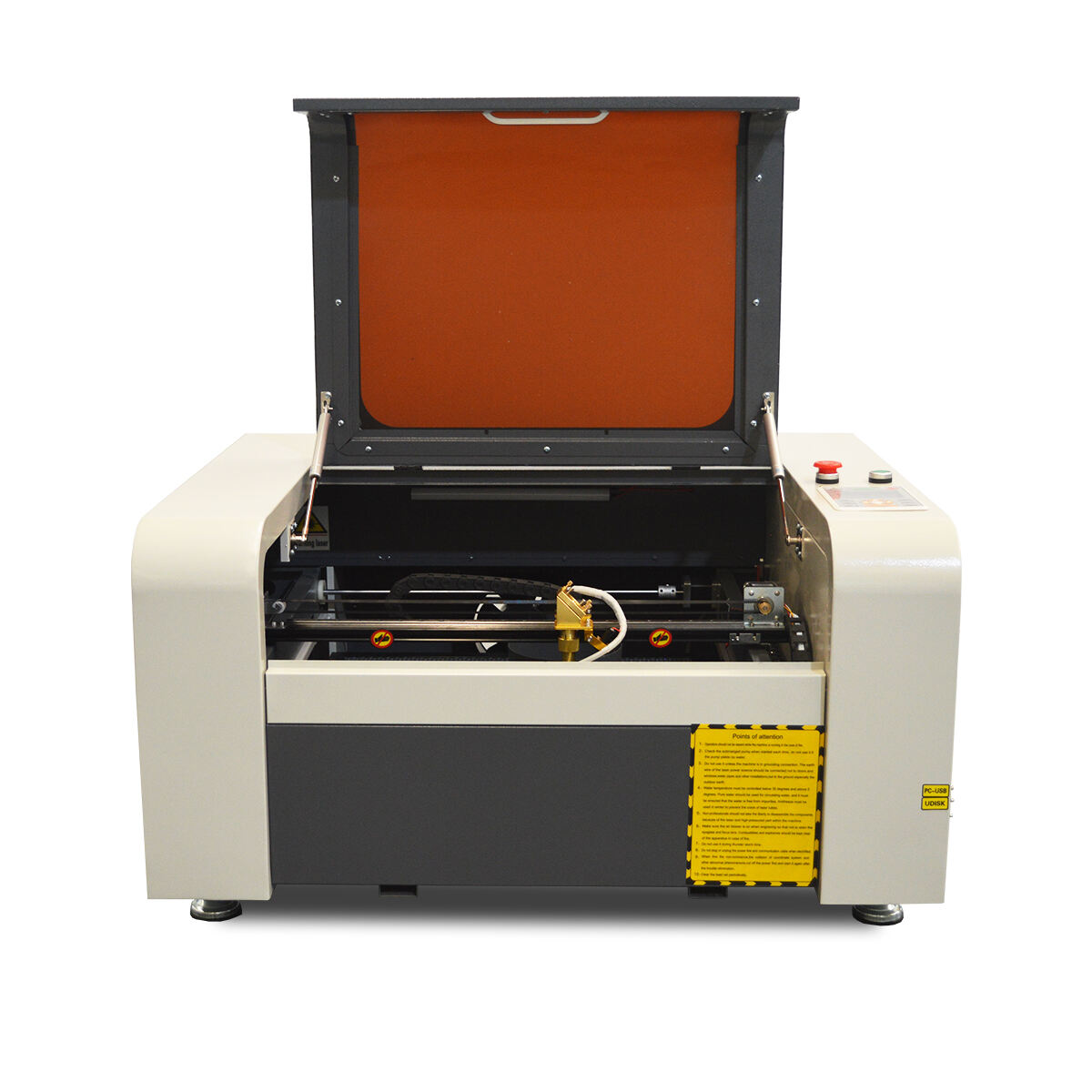

In metalworking shops, especially professional ones, the tools make all the difference. A professional laser cutter is one of those things. This type of cutter works by focusing a powerful beam of light, sometimes referred to as the laser beam, on the material to be cut. It can be compatible with various metals, such as steel and aluminum. Heavy duty laser cutters are necessary simply because they can undertake more robust projects than smaller machines. When metal workers have to cut pieces with precision, so they use these heavy-duty machines. They cut through dense materials with speed and precision that save the shop time and money.

High-Quality Finish One of the reasons why heavy duty laser cutters are so important is because they can produce high-quality finishes. When technicians use a laser cutter, the metal has smooth edges. This is less work subsequent to cutting and that’s big relief in busy shops! Smooth edge is necessary for fitting parts together perfectly. Applying heavy duty laser cutter also allows upright employees to produce more intricate designs with no difficulty.

Large format laser cutting machine among other advantages is that they are very reliable straight from the factory. They may be able to work for long periods without shutting down. This is very important in a busy metal shop where time equals money. When a machine goes down, it can lead to delays and lost profit. When you buy for a brand such as Voiern, metal shops can believe the assurance that they are getting a machine that will serve them for many years. They are made tough for everyday use. Not to mention how user-friendly, easy-to-use many commercial laser cutters can be. This allows workers to train on them quickly, something critical when you’re training new workers. In summary, a heavy duty laser cutter is a required equipment for any professional metal workshop which allows speed and precision, reliability with simplicity of operation.

Heavy Duty Laser Cutters at Wholesale Prices

Where to Buy If you are in search of the right solution for cutting heavy duty materials, then investing in heavy-duty laser cutters is a great idea. Heavy Duty Laser Cutter Purchase When a metal shop is looking to purchase heavy duty laser cutter engraver, they want to find the best deals. Online is one of the best places to go. There are many online sources for heavy duty laser cutters at wholesale prices. Online shopping is convenient because it makes it simple for metal shops to shop prices with multiple sellers. They can tell which machine has the features they want and the best price.

Or, you can go to trade shows and industry conferences. There, companies show off their latest machines and tools. This is an excellent opportunity for metal cutting shops to see the laser cutters in person.” They can speak with the salespeople and ask questions about the machines. This often comes with in-event discounts. Voiern regularly takes part in trade shows, and it is a rare chance for shops to get a top-of-the-range cutter at an attractive price.

You could also check with local providers if you are looking for a heavy duty laser cutter. Occasionally, those suppliers will discount purchases or arrange for financing plans to make buying easier. Metal shops can check with local suppliers to see what material they have in stock. Creating a good relationship with a supplier can help you secure better deals in the future.

Finally, be sure to read reviews before purchasing a heavy duty laser cutter. User reviews are a great help in assessing the quality and functionality of the device. Knowing what others have to say can help metal shops make a more informed decision. Through these avenues metal working shops can locate heavy duty laser cutters for wholesale prices that they can afford and that will get the job done.

Do You Know The Benefits Of Heavy Duty Laser Technology In Metal Fabrication?

There are a number of benefits to the use of heavy duty laser technology for metal fabrication. One of greatest advantages is accuracy. Lasers can slice through metal with precision. This translates to each cut piece fitting into place perfectly. On industries where precision measurement is critical, this tool is indispensable. Workers can generate intricate designs without fear of errors.

Another advantage is speed. Heavy duty laser cutters will be able to work faster than the more traditional tools in cutting metal. That is to say, jobs can be finished on metal shops’ end faster. If a shop can work more quickly, it can take on more jobs and earn more money. Responsive turnaround times are appreciated by clients and can be the reason for returning business.

And the second one is the cost effectiveness of heavy duty laser technology. Though the price of the machine exceeds nominal amount, it won't cost anything in long run. Since laser cutters are so efficient, they consume less energy than other machines. They also use less material; the cuts are very fine and little metal gets wasted. This lets shops save money on both energy costs and materials.

Heavy duty laser technology is also very adaptable. It works with whatever type of metal, and thicknesses, you can throw at it. This means metal shops can have just one machine for a variety of projects. That means for example, a shop could cut everything from thin sheets to thick plates on the same Voiern heavy duty laser cutter apparatus without buying different machines.

Lastly, the use of lasers is a way for companies to keep employees safe. Using standard cutting methods can cause sparks and debris, which are unsafe. But laser cutting has certain risks. This contributes also to a safer working environment for all staff. In general, the benefits of heavy duty laser technology are clearly valuable in metal fabrication precision, speed, cost and safety wise.