Laser cutter engravers are machines that can cut or carve your designs on materials such as wood, cork, plexiglass, acrylic, leather and most kinds of fabric. Tools like this are extremely popular because they can create detailed and clean cuts or engravings with great speed. Think about painting a picture onto a block of wood, except instead of using a paintbrush, there’s an ultra-precise laser. With this technology, countless businesses are able to produce products that look professional and one-of-a-kind. Voiern provides fiber laser engraving equipment that are designed to work hard and still making things simpler and faster.

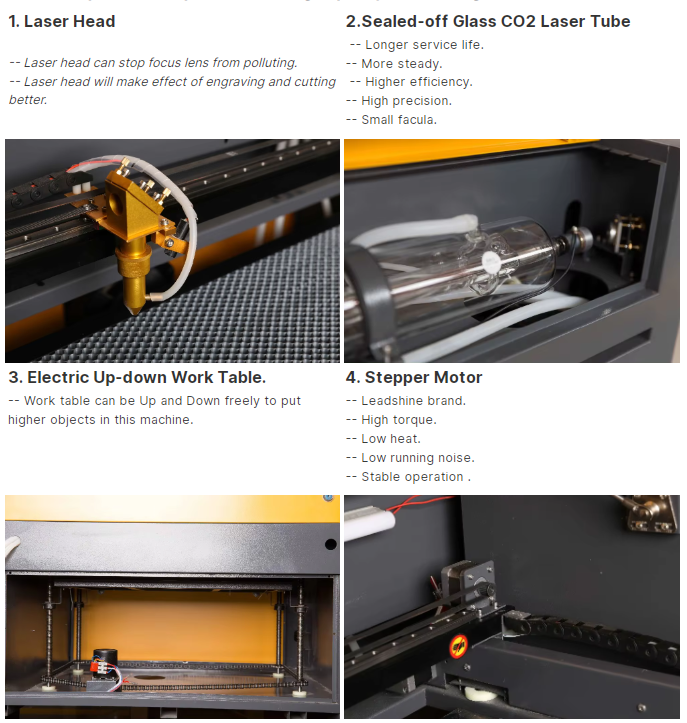

Laser cutters are unique machines that use a lot of to power to generate a very strong light beam that creates the design. There are tons of cool features in Voiern, among the advanced laser engraving equipment on the market today. One relevant characteristic is accuracy. In other words, the laser can rapidly cut or engrave very tiny and intricate shapes. It is like writing with a super sharp pencil that never errs. This makes possible that people can make stunning and intricate designs on things like wood, plastic or metal.

Another key feature is speed. Voiern’s high-quality laser cutter engravers operate quickly so you can get your large projects finished fast. That cuts down the time, especially if you’re preparing a large amount. These machines also have user-friendly software. On a computer, you can design your own patterns and then send them to the machine. The laser cutter engraver will read your design file as it is, nothing will change. This makes the process of creating personalized items such as jewelry, signs, and gifts quick & easy.

It can be a lot of fun working with a laser cutter engraver such as those available from Voiern, but things can go wrong. Understanding these types of issues and how to resolve them can keep you working smoothly and happily on your projects. One of the issues people run into often is that their laser isn’t cutting deep enough. This is frequently seen when the power settings of the laser are too low or if material thickness reached its limits. To fix this, you could bump up the power of your laser or decrease the cutting speed. This gives the Voiern Laser Welding Machine time and energy to penetrate straight through the material.

Another issue that users may experience could be the laser not aligning with the design as expected. This could be a computer file error or an issue with the machine setting. You can prevent this by double-checking your design file before you begin and ensuring the machine’s settings match the material you are using. It’s also a good idea to keep the machine clean. Dust and debris can obstruct the laser or diminish its efficacy. Cleaning the lens and the work area as part of regular maintenance helps the laser to operate better and longer.