Selecting the perfect fiber laser engraving machine for big orders can be a little challenging sometimes. You want a machine that can do lots of work daily without showing the first signs of stress. When I was new to working with fiber lasers, I found out that speed is one of the main things that is being focused on. A very slow machine will cause a long line of waiting orders to be formed - customers will most likely get impatient which is frustrating for them. Voiern’s Laser Welding Machine is built to keep up the pace but still be very steady. However, there are other things to be considered along with speed.

Using fiber laser engraving machines is a great method to assist different businesses and projects. These Laser Engraving Machine use a special kind of laser - a fiber laser - to separate or incise the materials with amazing accuracy and in less time. One of the coolest features of the fiber laser engraving is the way it produces a very high contrast and ultra-high definition look on metals like steel, aluminum, and brass. It's the perfect thing for use in jewelry making where tiny detailed designs are flawlessly made on rings, bracelets, and necklaces

Nameplates, trophies, and awards also derive great benefits from this because the words and images that are laser-engraved on the materials are very clear, crisp, and they do not get dirty or fade with the passage of time.

One of the reasons why a fiber laser is still among the most popular methods is that it is a non-disposable method. The laser is very precise, unlike some cutting and marking methods, which means that less waste is generated. This precision is allowing companies to cut costs while still lowering the pollution that is being produced. Fiber laser machines are very fast when they are operating, which, therefore, makes them capable of completing large amounts of work in a short period of time, a thing that is so valuable for companies with tight production schedules and a high-volume of output

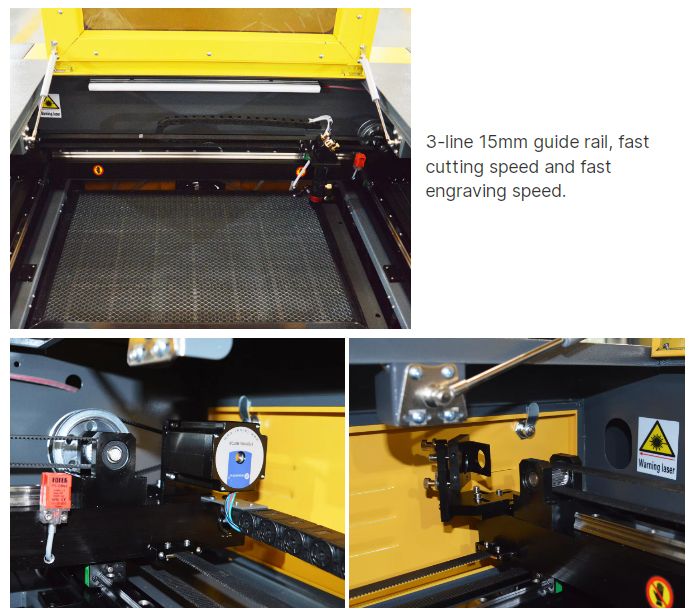

One of the equally very important maintenance methods is to check the moving parts of the machine. Typically, a fiber laser engraver is equipped with a motor and rails to change the position of the laser head. The parts should be oiled and checked for wear or any kind of deformation. The oiling attracts less friction, and that's why the CO2 Laser Engraving Machine runs better. If the components are already in quite a state of wear, doing a few replacements prematurely can stop bigger problems coming down the road.

Last, but definitely not least, in case you are using a fiber laser engraving machine, you should operate and take care of the machine following the instructions given by Voiern. After all, rightly trained operators are certainly the surest way of error prevention which, in the most unfortunate cases, can be very costly to the equipment. Sometimes it is quite difficult to recall when a certain thing was cleaned, checked, or repaired, and a record will assist you in keeping track of everything that has been done until now and thus ensures that the machine is in the best condition prior to your use. A fiber laser engraving machine, through these simple steps, will be able to stay in good shape and be a great help to the users in attaining the highest results for a long period of time.