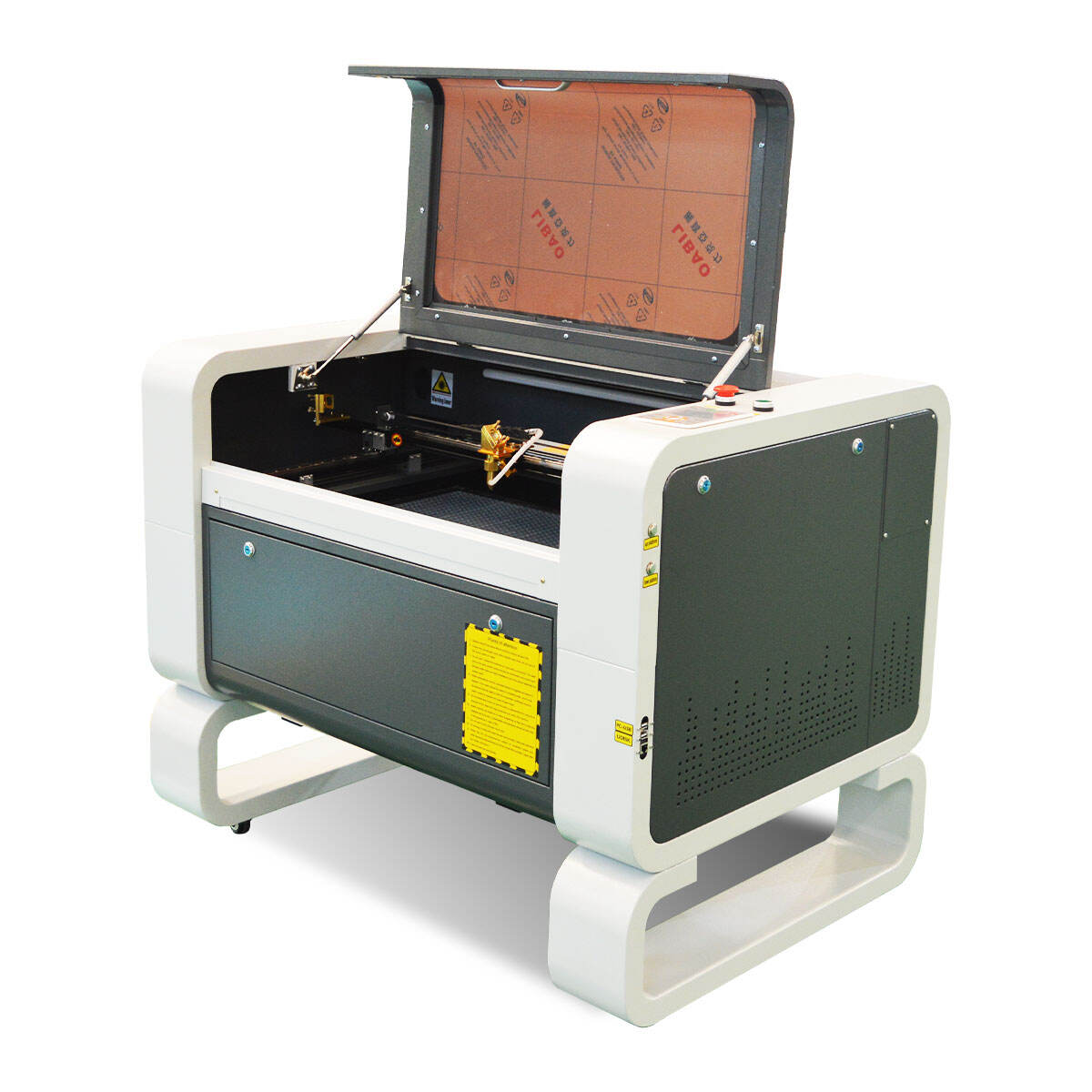

Machinae marcandi laser sunt praestationes technologiae concipi non posse, quae ad marcabundum varios materiae generis iuvant. Unum ex frequentissimis generibus est machina marcandi CO2 laser. Est machina quae CO2 laser utitur ad sculpendum vel marcabundum superficies quorundam materialium. Uti potest in materialibus ut ligno, vitro, plastice et corio. Intrantiae sicut Voiern, quae se specialiter habent ad hasce machinas conficiendas, aliis negotiis adiuvandis cum variis generibus marcandi. Ars marcandi CO2 laser celeris et accurata est, et ob hanc causam designa vel textus elegantes facile producere potest. Haec quoque machinae utilia sunt ad negotia quae vult branding, etichettas aut optiones personales offerre.

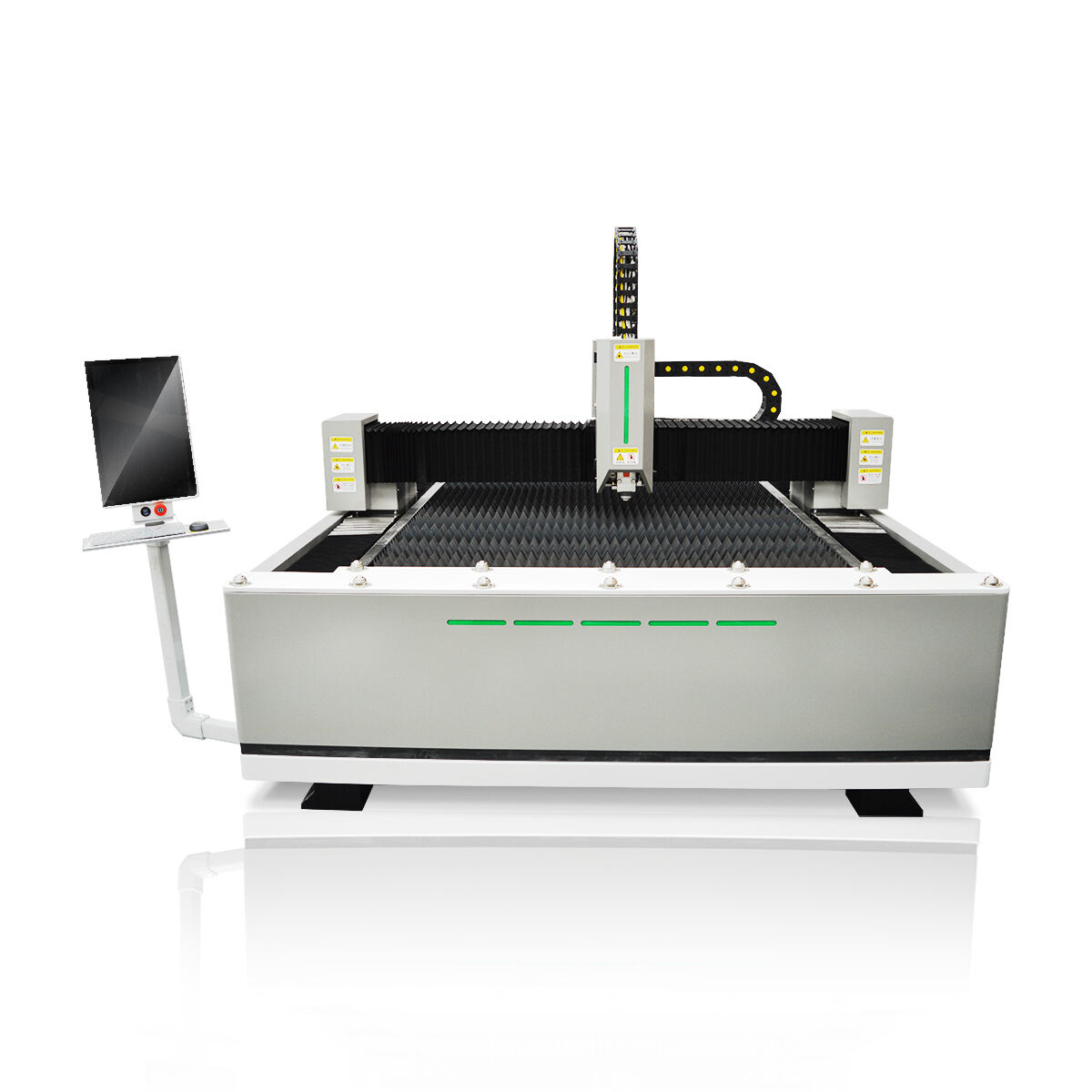

Fortasse multae res considerandae videntur, cum idoneam Machinam Marking Laser CO2 eligis, sed difficile non esse debet. Primo considera quae materialem tu notabis. Aliquae materiales melius in quibusdam machinis operantur. Verbi gratia, si lignum vel acrylicum laseri caesum velis, tunc unam opus est, quae specialiter ad hoc sit parata. Deinde cogita quid notabis. Si producta quae incisas magna sunt, opus habebis machina laser ad notandum cui maior area operandi sit. Nos variis magnitudinibus praestamus, ut quod tibi optimum sit eligas.

Aspecta etiam functiones! Aliae machinae cum software specializato conbunduntur ut tibi adiuvandus sint in creando propriis notis. Hoc valde utile esse potest cum formas tuas designas. Machinae Voiern plerumque simplicem softwaren designandi includunt quae facile est ad usandum. Etiam considerare velis quam facilis sit machina ad purgandum. Machina quae facile purgari et reparari potest tempus multum et laborem tibi pepercerit. Denique, cogita de tuo pecuniae modulo. Pretium machinarum signatoriarum CO2 valde variat. Apud nos aliquid pro diversis modulis habetur, itaque certe aliquid invenies quod tibi conveniet nec sinum vacuum efficies.

Machina Signatoria CO2 pro ampla varietate industriae. Signator laser CO2 auxilium eximium est in multis industriae. Machina tamen, ut aliae, defectibus laborat. laser sculpendisque et sculpendis machina . Unum e communibus problematis est, quod laser non sculpit tam profunde vel pure. Causae huius rei plures esse possunt. Primo, productum marcandum fortasse ad marcabiliam per laserem non sit idoneum. Exempli gratia, quaedam plastica aut superficies tractata non adeo bene lucem laseris absorbent, itaque signa valde infirma fiunt. Ad hoc corrigendum, materiae omnem differentiam faciunt. Si certus es te marcaturum, vide num bene cum laseribus CO2 functionet.

Si in ambiente manufacturandi usantur, machinae marking CO2 velocitatem et efficaciam garant. Id efficiunt celeritatem processus marking augendo. Veteres methodi, ut signatio et scalptura, tempus longum poscere possunt. CO2 laser item cito et precise marcare potest, ita ut societates amplius in minore tempore producere queant. Hoc illis facultatem dat celerius ad petitionem clientium respondendi et lineas productionis constantissime movendas.

Praecisio etiam aliud bonum CO2 machinarum notantum est. Haec machinae notae valde tenuis effingere possunt, quod pro notabilitate, vestigiis sequendis, etc. necessarium est. Verbi gratia, commercia sua signa vel alia informatione necessaria in suis rebus imprimere possunt. Haec non solum rei obiectae gratia est, sed etiam cliente facile agnoscenda. Hoc optimum est, quia non solum pauciores fiunt errores quibus granis uti possis, sed etiam tempus et rem servas.

Praeterea, machinae notantes CO2 valde versatiles sunt. Cum variis materiae generibus uti possunt, inter quas lignum, vitrum et plasticum. Quod eo quod fabricatores iam eandem machinam pro variis rebus uti possunt, nec opus est ut instrumenta singula mutent. Haec versatilitas productionem faciliorem et celeriorem efficit. Praeterea, machinae saepe simplices ad programmandum et operandum sunt, itaque operarii relative cito doceri possunt quomodo utantur. Cum Voiern aparatus incisionis laser , fabricantes temporis etiam efficiendi productionis extremi gratia pecuniam salvam facere possunt.