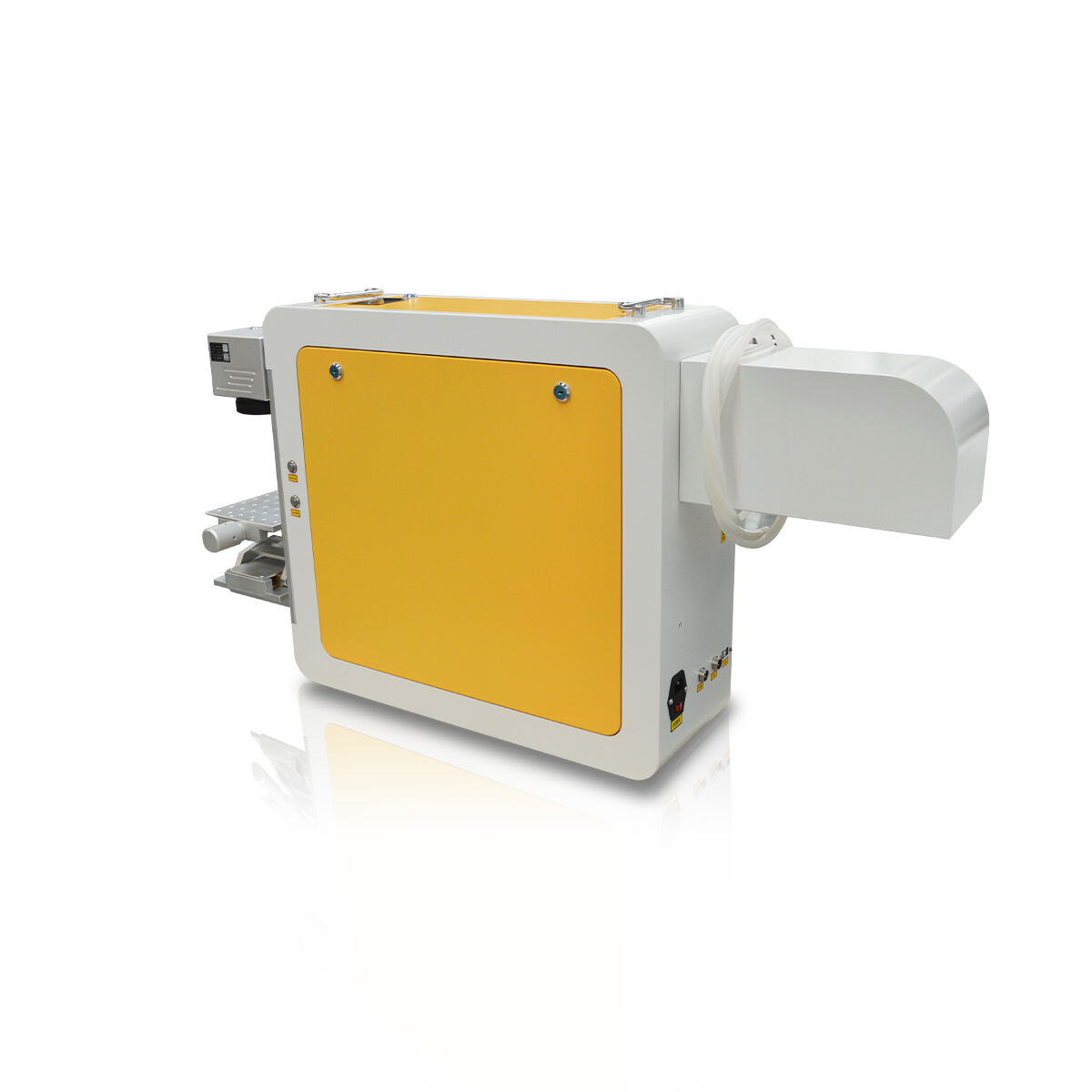

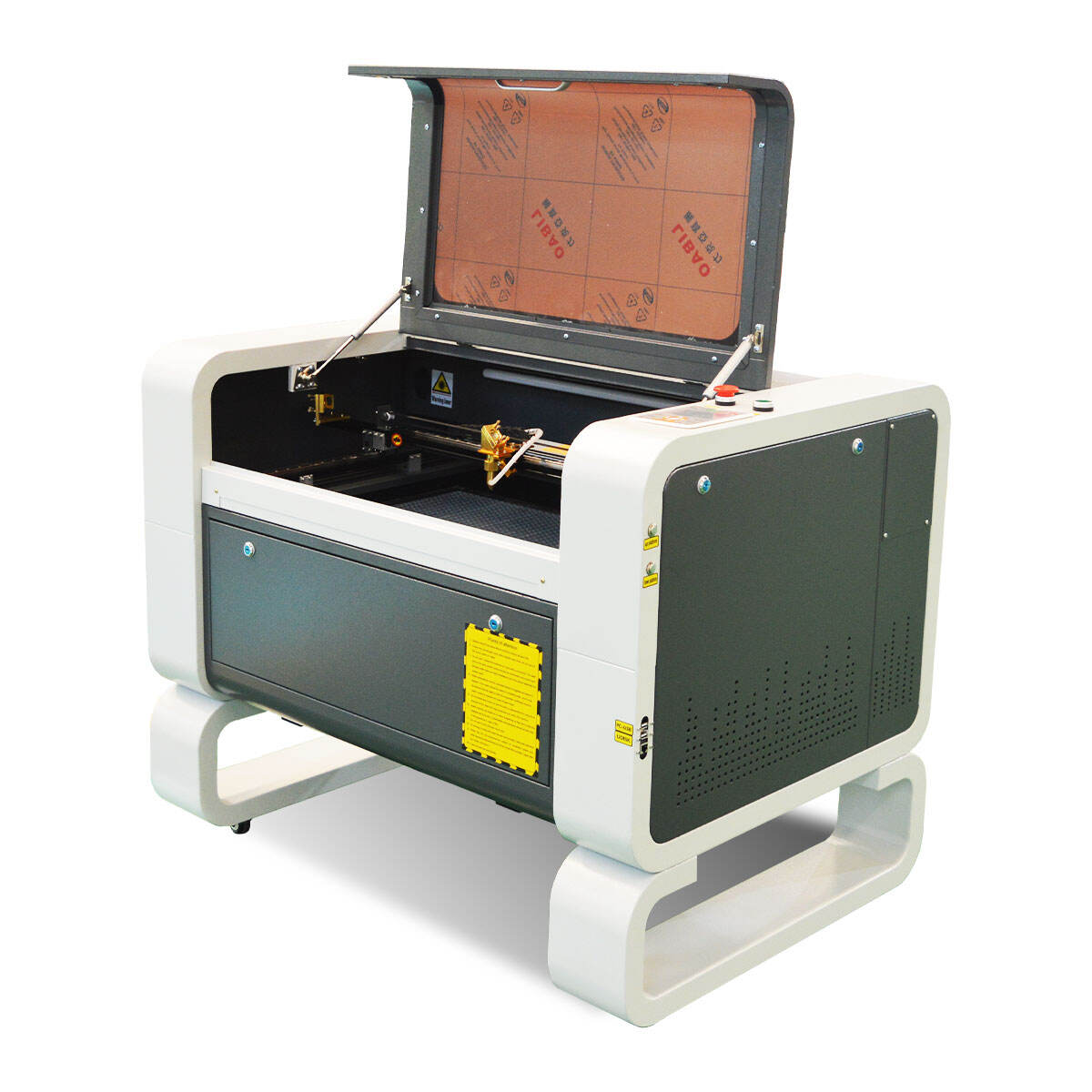

A fiber laser cutter is a cutting tool that uses a high power laser beam to cut different types of materials such as metal, steel, wood, acrylic among others. It has a very thin, strong laser. This laser never comes into contact with the material, but is capable of cutting through the material very accurately. Imagine you want to create a sweet sign for your brand, "Voiern." A fiber laser cutter can handle that quickly and neatly. These machines are useful in factories and workshops because they enable things to be made more quickly than with older methods. Saving power is another advantage, and the environmental benefits are obvious there. Users of the fiber laser cutter are able to make small, intricate patterns that would be difficult with other machines. It’s as if you were drawing with a light pen that shaves material away or incises rather than inks its lines on paper.

When trying to decide which fiber laser cutter is perfect for you, there are a few factors that must be taken into consideration. To do this, take into consideration the materials you will be working with. Are they thick or thin? If you want to make cuts in thick metal, you need a lot of power behind your machine. You also need to compare the cutter size. A bigger bed should allow you to cut larger pieces, but requires more room. You should also take into account how quickly you would like to work. Some machines are super fast at cutting, which can help you stay on your aggressive schedule. You may search for features such as automatic height adjustment, functionalities that keep the laser at an optimal distance from material. This helps make better cuts. Reliability is another big point. You’re looking for a machine that won’t break down on you after a few years. Select from a company such as “Voiern” which can offer you good support while learning to use your machine. Speaking to other business owners who work with fiber laser cutters can also provide you with valuable information about things that work best for them as well.

Securing a great deal on quality fiber laser cutters is crucial for any business owner. A great way to get some is to search on the web. These machines are available at reduced rates in many websites for bulk purchases. Look at reviews to get an inkling of how people are reacting to the products. Or you can go to trade shows. These are great venues to get up close and personal with those machines and pose your questions directly to the manufacturers. Companies may offer prices that are only available to those who attend trade shows. Networking with other business owners can actually uncover exclusive deals on fiber laser cutters as well. Be sure to watch for discounts or specials. From time to time you may find a seasonal sale or special offer going on at "Voiern ". And you can also always ask businesses in your area for help finding reasonable prices or for introductions to suppliers. This can save you the cost and time to try out your new fiber laser cutter for yourself.

Many businesses will find gesture using fiber laser cutting machines, and sooner or later they may also encounter some questions. When the machine doesn’t cut just so, one of the major problems is. The cuts can sometimes be jagged rather than neat. This may occur if the machine’s focusing lens is dirty or incorrect settings are used. For instance, the power settings aren't high enough to where it might not cut through the material -> EdgeInsets all around. Users are also faced with the issue of maintenance. Fiber laser cutters are mighty machines, but they require regular maintenance and repair in order to work at their full capacity. If components such as the cooling system are not inspected, the machine can overheat and fail. People need to watch that sort of thing so they don’t get in trouble.” For some people, it is also difficult to learn how to use the machine correctly. Each machine has different controls, and new users may not know how to tweak the settings for various materials. This is frustrating and wasteful. And, there can be difficulties with users finding the right materials to cut. While some materials do better than others when cut by a laser. For example, metals make great cuts, however they may lose while thick steel. These are really tough issues, but they can be addressed with the right education and support. Thankfully, companies like Voiern offer helpful resources and guides that help users conquer these common issues and slash their way to perfection.

Fiber laser cutters are increasingly being considered for manufacturing as manufacturers are looking to make it easier and faster. These machines are capable of cutting the materials a lot faster as compared to the manual cutting tools. This allows factories to make more items in shorter periods of time. The faster you make products, the more money they can make because they can sell more of them. They don’t have to wait as long to complete their work.” And fiber lasers are very accurate. They can be used to make cuts that are thinner than a hair on your head. This translates into less waste, as the materials are utilized to a greater extent. They can use nearly everything they cut instead of discarding pieces of metal or other materials. This is not just saving money but also helping the environment. This is how smarter companies, such as Voiern, are taking the lead over their competitors. Fiber laser cutters allow them to produce higher quality products faster. One of the advantages is that it’s straightforward to work with fiber lasers. A lot of machines have user-friendly controls that help employees more easily learn how to use them. That saves on training time, and makes workers happier because they can do their jobs better. Plus, with computers and software linked to the fiber laser cutters, production can be automated. That’s less error and more predictability in the work performed. In short, fiber laser cutting systems provide increased production rates and the ability to process different types of materials (like aluminum, copper, and brass) in a more efficient manner. One such area that it is being applied to in a major way is the development of efficient manufacturing procedures by companies like Voiern.